In the realm of industrial valve applications, the plug valve stands out as a crucial component, offering unique benefits and versatility across various sectors. According to a recent market analysis by ResearchAndMarkets, the global industrial valve market is projected to reach USD 88.4 billion by 2027, driven in part by the increasing demand for effective fluid control systems.

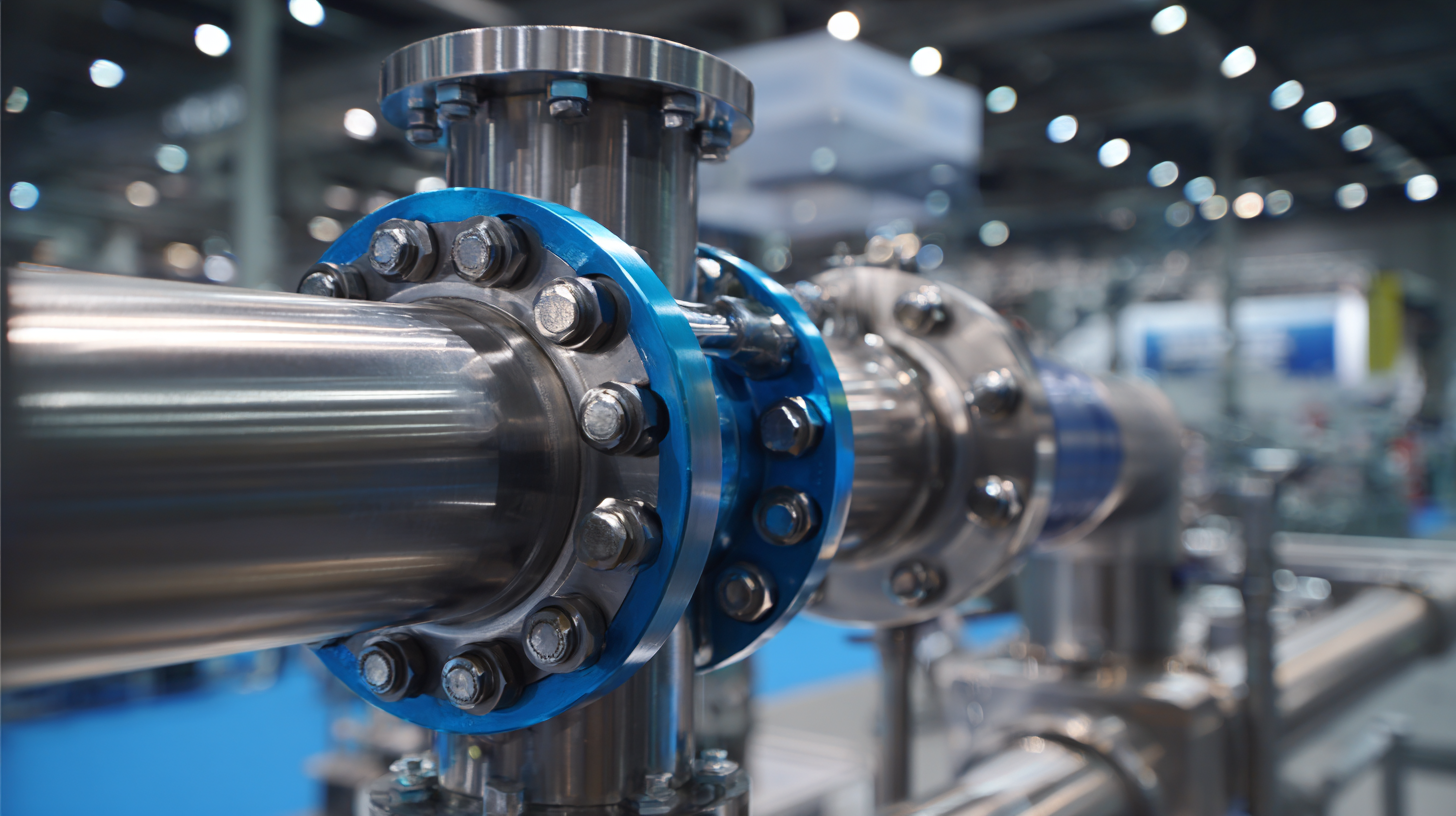

Plug valves, with their simple design and robust sealing capabilities, are integral to sectors such as oil and gas, water treatment, and pharmaceuticals. These valves are particularly valued for their ability to handle viscous fluids and slurries, demonstrating operational reliability under high pressures and temperatures.

This guide aims to delve deeper into the applications and benefits of plug valves, providing insights that can help industries enhance their fluid management systems and optimize operational efficiency.

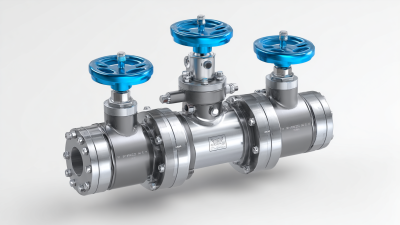

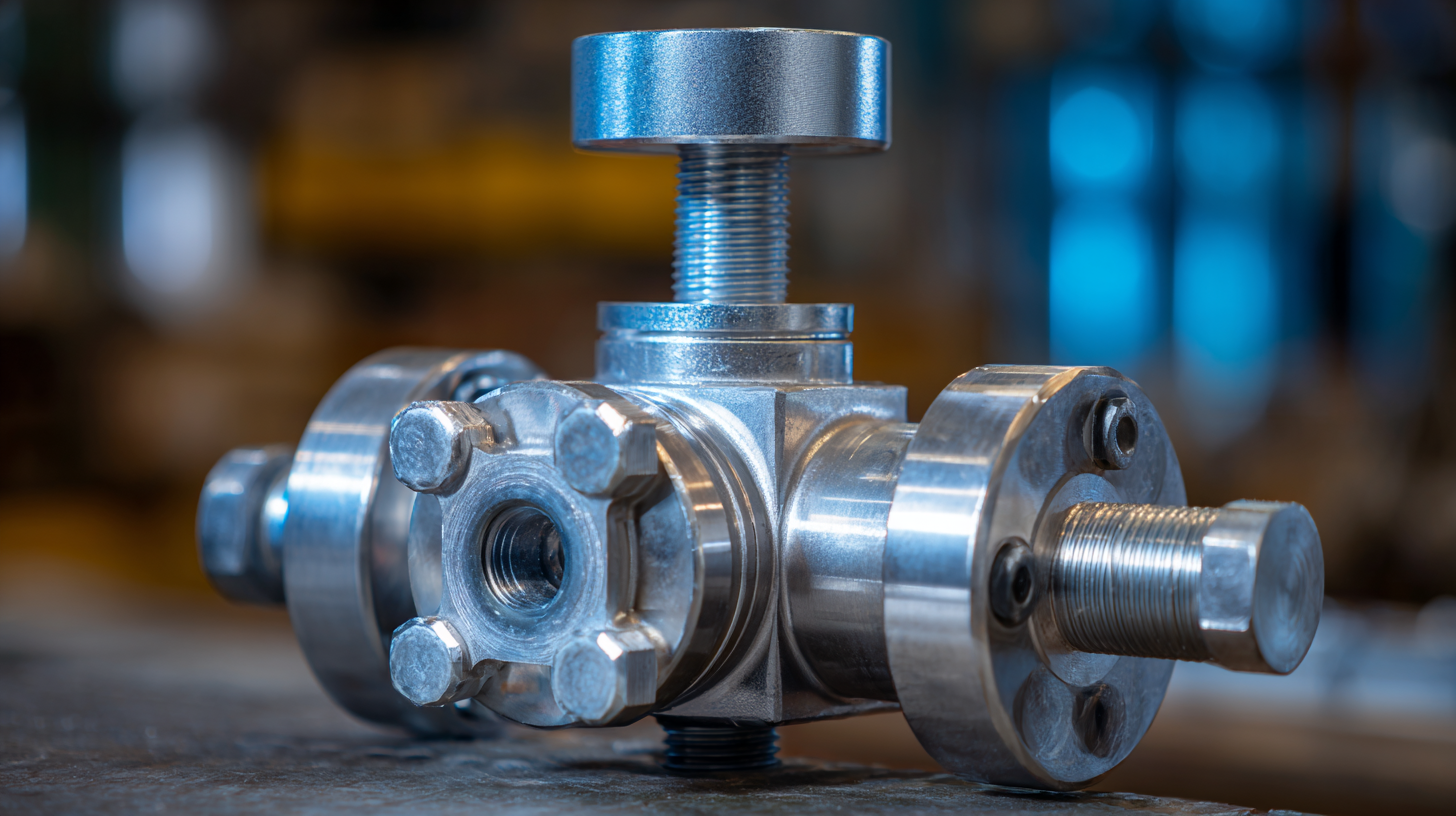

Plug valves are versatile components widely used in various industries due to their simple design and reliable performance. There are several types of plug valves, including straight and tapered designs, each serving distinct purposes based on the application. Straight plug valves provide a higher flow capacity, while tapered plug valves are ideal for applications requiring tight sealing. The mechanism of a plug valve features a cylindrical or conically tapered plug that rotates to control flow, allowing for quick shut-off and easy maintenance.

The operation of plug valves is straightforward, enabling them to handle both liquid and gas applications. When the plug is turned a quarter turn, it aligns with the pipeline to allow flow or misaligns to obstruct it. This feature makes them particularly advantageous in situations where space is limited, as the actuation is quick and requires minimal effort. Additionally, the absence of dynamic seals in most designs reduces the risk of leaks, further enhancing their reliability in demanding environments.

Plug valves are widely utilized across various industries, thanks to their unique design that allows for efficient flow control. In the oil and gas sector, for instance, plug valves are favored for their ability to handle high-pressure applications and corrosive materials, making them ideal for upstream extraction processes.

According to a report by Research and Markets, the global plug valve market is expected to grow significantly, reaching $5.81 billion by 2027, driven by increased investment in oil and gas infrastructure.

In the chemical processing industry, plug valves provide reliable sealing capabilities, crucial for preventing leaks during the transportation of hazardous materials. Their simple operation and low maintenance requirements enhance their application in environments where shut-off reliability is essential.

The Chemical Engineering magazine highlights that around 30% of valve failures in chemical plants can be attributed to poor sealing performance, underscoring the importance of choosing the right valve type, like plugs, for specific applications.

Tip: When selecting a plug valve, consider the materials of construction to ensure compatibility with the fluids being transported. Regular maintenance checks can help extend the lifespan of the valve and prevent costly downtime.

Another critical application of plug valves is in water treatment facilities, where they help manage the flow of water and waste efficiently. According to the American Water Works Association, proper valve selection in these systems can reduce water loss by up to 20%, significantly improving resource management.

Tip: Implementing a routine inspection schedule for plug valves can prevent operational issues and ensure a more environmentally sustainable operation.

Plug valves are becoming increasingly popular in fluid control applications due to their unique advantages over other types of valves. One standout benefit is their excellent sealing capability, which is essential when dealing with high-pressure fluids. According to the Valve Manufacturers Association, plug valves have a leak rate of only 0.1% at maximum pressure, making them an ideal choice for industries requiring stringent leak prevention, such as oil and gas and chemical processing.

When considering plug valves for your next project, it’s essential to note their ease of operation. With a simple quarter-turn mechanism, operators can quickly open or close the valve, making them highly efficient for systems with frequent on-off cycles. A report by the American Society of Mechanical Engineers indicates that using plug valves can reduce operational time by up to 20%, enhancing overall productivity.

Tip: Always ensure that the material of the plug valve is compatible with the fluid being controlled to prevent corrosion or chemical reactions that can compromise the valve’s integrity. Additionally, routine maintenance checks can significantly extend the lifespan of the valve and ensure optimal performance in critical applications.

When selecting plug valves for industrial applications, several crucial factors come into play to ensure optimal performance and longevity. Firstly, the materials of both the valve body and the plug must be compatible with the fluid being controlled. For example, if dealing with corrosive substances, opting for materials such as stainless steel or specialized alloys is essential to prevent degradation and maintain reliability. Additionally, consideration of temperature and pressure ratings is vital, as exceeding these limits can lead to valve failure and safety hazards.

Another significant factor is the valve design. Different configurations, including resilient-seated and metal-seated designs, cater to distinct operational needs. Resilient-seated plug valves offer a tight seal, ideal for applications requiring zero leakage, while metal-seated variants are better suited for high-temperature and high-pressure environments. Lastly, one should assess the ease of maintenance and repair, as accessibility can greatly impact downtime and operational efficiency. Prioritizing these factors will lead to a more informed choice, ultimately enhancing the effectiveness of your fluid control systems.

| Dimension | Details |

|---|---|

| Type of Plug Valve | Lubricated, Non-lubricated, Quick-opening |

| Common Applications | Oil and gas, Water treatment, Chemical processing |

| Size Range | 1/2 inch to 12 inches |

| Temperature Range | -20°C to 200°C |

| Pressure Rating | 130 psi to 1500 psi |

| Material Options | Cast iron, Stainless steel, Bronze |

| Benefits | Robust sealing, Simple operation, Minimal maintenance |

| Key Considerations | Operating environment, Flow type, Maintenance capabilities |

When it comes to maintaining plug valves, understanding the best practices is crucial for ensuring their longevity and optimal performance. Plug valves, which are known for their ability to provide a tight seal with minimal leakage, require regular maintenance to prevent issues such as corrosion or debris buildup. It is essential to conduct routine inspections, focusing on the valve operability and condition of the seals. Regular lubrication can also help in reducing wear and tear, ensuring the valve operates smoothly.

Additionally, adhering to the manufacturer's guidelines during maintenance is important. For instance, while changing oil in hybrid systems doesn't usually require disconnecting the system, similar principles apply when servicing plug valves. Following specific maintenance protocols can help avoid missteps that could compromise the valve's function. Utilizing appropriate lubricants and replacement parts can further extend the life of the valve, making it more efficient in various industrial applications. By incorporating these maintenance best practices, operators can ensure that plug valves continue to perform effectively over time.