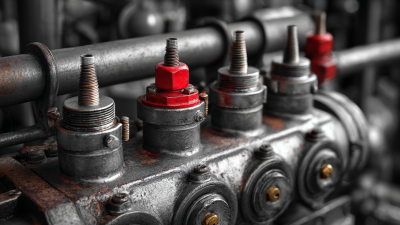

In the realm of industrial applications, piston valves play a pivotal role in regulating fluid flow and pressure across various systems. However, like any mechanical component, they are not immune to issues that can hinder performance and efficiency. This blog aims to delve into the common complications encountered with piston valve applications and provide insightful troubleshooting strategies to address them effectively.

From improper sealing and actuation problems to issues related to material compatibility and maintenance practices, understanding these challenges is crucial for ensuring optimal operation. By exploring real-world examples and practical solutions, we hope to equip professionals with the knowledge needed to enhance the reliability and longevity of piston valves in their industrial settings.

From improper sealing and actuation problems to issues related to material compatibility and maintenance practices, understanding these challenges is crucial for ensuring optimal operation. By exploring real-world examples and practical solutions, we hope to equip professionals with the knowledge needed to enhance the reliability and longevity of piston valves in their industrial settings.

When faced with challenges in piston valve applications, it’s essential to explore alternatives that can better meet the demands of industrial settings. One such innovative solution is the

use of diaphragm valves, which provide a reliable seal and reduce the risk of leaks. These valves are ideal for applications involving corrosive or abrasive materials, enhancing system longevity and efficiency.

Tips: When considering diaphragm valves, ensure the material compatibility with your process fluids. Additionally, regular maintenance checks can prevent blockages and prolong service life.

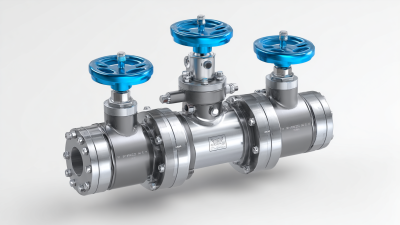

Another promising alternative is the use of ball valves. Known for their quick operation and minimal pressure drop, ball valves can handle high flow rates and are less prone to wear compared to piston valves. Their simplicity in design also makes them easier to maintain and repair.

Tips: Always select the right size and rating for your application. Implementing an automated control system can further enhance performance and reduce manual intervention, leading to a more streamlined operation.

When considering valve technologies for industrial applications, one often finds themselves at a crossroads between piston valves and alternative valve systems. Piston valves, known for their robust construction and reliable performance under high-pressure conditions, excel in providing tight sealing and controlled flow. Their unique design allows for efficient operation, especially in demanding environments where precision and durability are essential. However, they can be more complex to install and maintain compared to simpler valve designs.

On the other hand, alternative valve technologies, such as ball and gate valves, offer distinct advantages in terms of maintenance and ease of use. Ball valves feature a straightforward operation that allows for quick on/off control, making them ideal for applications requiring rapid flow adjustments. Gate valves, while not as efficient in flow regulation, are favored in situations where minimal pressure drop is crucial. The choice between these valve types ultimately hinges on the specific requirements of the application, including factors like space constraints, fluid characteristics, and the criticality of precise flow control. Understanding these differences enables engineers to make informed decisions that maximize operational efficiency and reliability.

When evaluating the performance of pneumatic systems, it's essential to consider the application and the specific requirements. In sectors dealing with low capacity commercial vehicles, for instance, the assessment of pneumatic engines is crucial. These systems can offer various benefits, such as lighter weight and energy efficiency, but they may also present limitations in specific operational scenarios. This brings us to the question of when it might be more advantageous to opt for alternatives to piston valves.

Piston valves are known for their reliability and simple operation in many industrial settings; however, they may not always be the best choice in every situation. For applications that demand rapid response times or require handling of viscous fluids, alternatives like diaphragm valves or ball valves can provide better performance. Analyzing performance parameters—similar to how pneumatic engine evaluations focus on efficiency and responsiveness—can guide professionals in making the right choice for their specific needs. Assessing the unique challenges and operational demands of your application is key to optimizing system performance.

In today’s industrial landscape, the choice of valve types significantly impacts both operational efficiency and cost-effectiveness. Piston valves, while known for their robust design and precise control, can sometimes present challenges such as leaks and maintenance issues. According to a recent report by the International Journal of Engineering Research & Technology, the average annual maintenance costs for piston valves can reach up to 15% of their initial purchase price, which can be a substantial burden for companies operating on tight margins.

Alternative valve types, such as butterfly and ball valves, often offer a more cost-effective solution without compromising performance. A study from the Valve Manufacturers Association indicates that both butterfly and ball valves have lower installation and maintenance costs, potentially reducing operational expenditure by 10-20%. Moreover, the rapid opening and closing capabilities of these alternatives can enhance system efficiency, aligning with the industry's increasing focus on automation and energy savings. As industrial operations evolve, evaluating the cost-effectiveness of valve types becomes crucial for driving long-term profitability and sustainability.

Transitioning from piston valves to alternative solutions in industrial applications can present a range of challenges. One of the most significant hurdles is understanding the specific requirements of the system and how different valve types can fulfill these needs. For instance, while piston valves offer reliable performance in many contexts, their mechanical complexity can lead to maintenance difficulties and operational inefficiencies. When shifting to alternatives such as solenoid or diaphragm valves, it's crucial to assess not only the technical specifications but also the compatibility with existing infrastructure.

Another critical aspect of this transition lies in the training and adaptation of personnel. Workers accustomed to handling piston valves may require additional education to understand the operational nuances of new valve types. This can include learning about the different maintenance protocols, troubleshooting techniques, and performance characteristics associated with the chosen alternative. Addressing these knowledge gaps ensures a smoother integration process and maximizes the operational efficiency of the new system. By proactively managing these challenges, organizations can successfully navigate the complexities of this transition and optimize their valve applications.