In the realm of industrial automation and process control, control valves play a pivotal role in regulating fluid flow and ensuring optimal performance across various applications. According to a recent market research report by Technavio, the global control valve market is expected to grow by over 10% annually through 2025, underscoring the increasing demand for efficient and reliable control systems in industries such as oil and gas, water treatment, and chemical processing. As industries continue to evolve, understanding the different types of control valves and their specific applications has become essential for engineers and operators alike.

Expert insights further highlight the importance of selecting the right control valve type to achieve desired outcomes. Dr. Emily Roberts, a leading figure in fluid dynamics and control systems at the Institute of Process Control, emphasizes, “The choice of control valve can significantly influence process efficiency, safety, and cost-effectiveness. A well-selected control valve not only optimizes flow control but also enhances overall system performance.” As we delve into the top 10 control valve types, it becomes evident that comprehending their functionalities and unique advantages is crucial for maximizing operational efficiency and maintaining competitive edge in today’s fast-paced industrial environment.

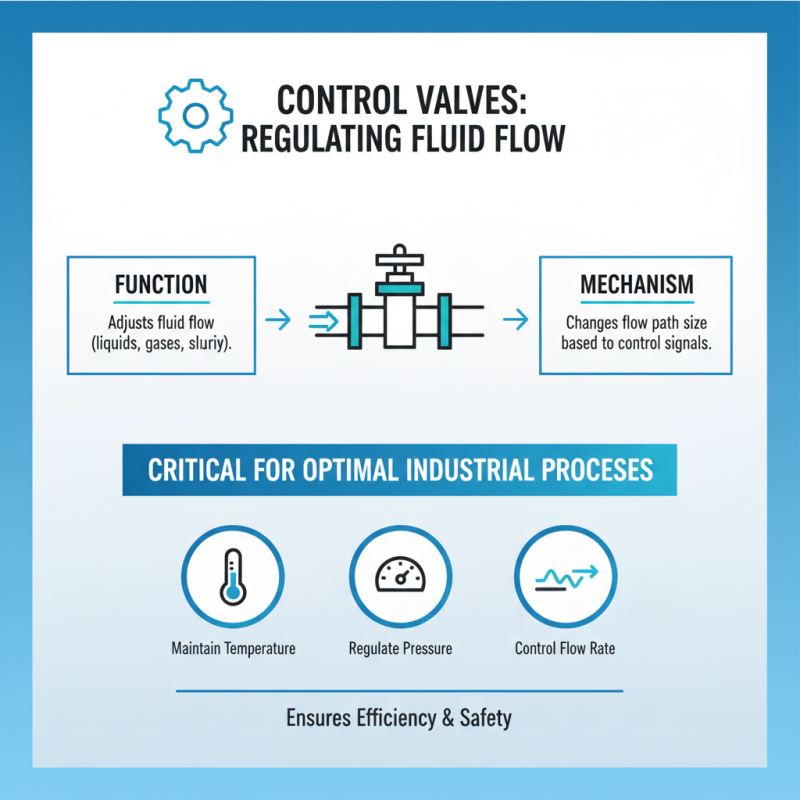

Control valves play a critical role in regulating fluid flow within various systems, ensuring optimal performance in industrial processes. As defined, these mechanical devices adjust the flow of liquids, gases, or slurries by changing the size of flow paths according to control signals. This capability is essential for maintaining desired parameters like pressure, temperature, and flow rate, which are crucial for the efficiency and safety of many operations.

The global market for control valves is projected to experience substantial growth, with estimates indicating a market size of $2.26 billion in 2024, expected to rise to $3.45 billion by 2033, reflecting a compound annual growth rate (CAGR) of approximately 4.81%. This growth is driven by increasing demand across various sectors, including pharmaceuticals, oil and gas, and water treatment, where precise flow control is vital. The continuous advancement in control valve technology, focused on improving performance and reliability, further supports this upward trend in market dynamics.

Furthermore, as industries increasingly adopt automation and smart technologies, the integration of advanced control valves will be vital for enhancing process efficiency and sustainability. The expanding applications in emerging markets, coupled with the enhanced focus on energy efficiency and resource management, are likely to shape the future landscape of the control valve industry.

Control valves play a vital role in industrial processes by regulating flow and pressure, ensuring that systems operate within their desired parameters. According to a report by Global Market Insights, the control valve market is projected to reach over $10 billion by 2026, demonstrating a growing recognition of their importance in optimizing performance across various applications. In processes such as chemical manufacturing and water treatment, the precise modulation of flow and pressure can lead to enhanced efficiency and reduced energy consumption.

The functionality of control valves is primarily determined by their ability to respond to changes in system dynamics. For instance, smart control valves equipped with advanced automation technologies can significantly improve response times and accuracy in regulating flow rates. A study by the International Society of Automation highlights that implementing such technologies can reduce operational costs by up to 15% while improving system reliability. Control valves, therefore, are not merely passive components; they actively contribute to maintaining optimal conditions in numerous applications, displaying their critical role in modern engineering solutions.

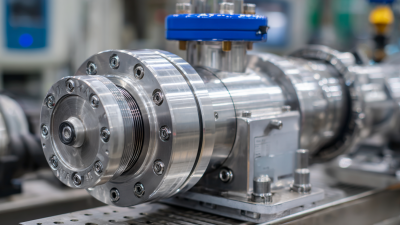

Control valves play a crucial role in regulating flow, pressure, and temperature in various industrial processes. Understanding the different types of control valves and their unique characteristics is essential for achieving optimal performance.

One of the most common types is the globe valve, known for its excellent throttling capability and versatility in flow regulation. Its design allows for higher resistance to flow, making it suitable for applications requiring precise control.

Another popular type is the ball valve, recognized for its quick operation and low-pressure drop. These valves feature a spherical disc that provides a straight-line flow path, which minimizes turbulence and enhances efficiency.

Additionally, butterfly valves are favored for their compact design and lightweight construction, making them ideal for large diameter piping systems. Each valve type offers particular advantages that cater to specific operational needs, and selecting the right one can significantly impact system performance and reliability.

When selecting a control valve, several key factors should be considered to ensure optimal performance. Firstly, the application requirements play a critical role—whether the valve will be used in manufacturing processes or healthcare settings can influence the type chosen. The fluid characteristics, such as temperature, pressure, and flow rate, also significantly impact valve performance. Understanding these factors is essential in determining the suitable materials and design for the valve.

Moreover, the actuation method is another important consideration. Control valves can utilize various actuators, including electric, pneumatic, and hydraulic types. Each actuator type has its advantages depending on the specific application and operational needs. For instance, electric actuators can offer precise control in complex systems, while pneumatic actuators might be preferred for faster response times.

**Tips:** Always evaluate the total cost of ownership, including maintenance needs and downtime. Consider the growth potential in your industry; for example, sectors like the EEG systems market are projected to grow significantly, which might affect how control valves are utilized in future applications. Staying informed about market trends can provide insights into making better choices regarding control valve selection.

| Valve Type | Description | Key Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Globe Valve | A valve with a spherical body used for flow regulation. | Chemical processing, water treatment | Good throttling capability | Relatively higher pressure drop |

| Ball Valve | A valve with a spherical closure element that controls flow. | Oil and gas, water distribution | Quick to open/close, low pressure drop | Not suitable for throttling |

| Butterfly Valve | A valve that uses a rotating disc to control flow. | HVAC, water supply | Lightweight, compact design | Limited throttling capabilities |

| Gate Valve | Used for on/off control of flow. | Water supply, oil pipelines | Low pressure drop, effective sealing | Not suitable for throttling |

| Check Valve | Prevents backflow in a piping system. | Pumping stations, water systems | Automatic operation, prevents backflow | May cause pressure drop |

| Pressure Relief Valve | Used to release excess pressure from a system. | Boilers, pressure vessels | Prevents system overpressure | Requires regular maintenance |

| Solenoid Valve | Electrically operated valve for precise control. | Automated systems, irrigation | Fast operation, compact | Limited flow capabilities |

| Diaphragm Valve | Uses a flexible diaphragm to control flow. | Water treatment, pharmaceuticals | Excellent for corrosive fluids | Limited flow rates |

| Pinch Valve | Controls flow by pinching a flexible tube. | Slurry and powder handling | Good for dirty fluids | Limited in use cases |

Proper maintenance and troubleshooting are essential for ensuring optimal performance of control valves in any industrial setting. Regular inspection of control valves can identify potential issues before they escalate into major problems. Routine checks should focus on leak detection, ensuring that seals and packing are intact, as well as observing the valve's operation for any irregularities. Additionally, cleaning the valve components, such as grates and seats, can prevent buildup that might impair functionality.

When troubleshooting control valve performance, it is important to understand the symptoms of common problems. For instance, if a valve is failing to open or close properly, it may indicate a malfunctioning actuator or an obstruction within the pipeline. Calibrating the positioner to ensure it responds appropriately to control signals can also resolve issues related to responsiveness. Keeping a detailed log of maintenance activities and performance observations aids in predicting potential failures and refining troubleshooting strategies, ultimately contributing to a more efficient and reliable control system.