In fluid control systems, precision and reliability are paramount. Among the various components that contribute to the effective management of fluid flow, the swing valve stands out as a crucial element. A swing valve is designed to control the direction and flow of fluids in a system by utilizing a pivoting disc that swings open or closed. This unique mechanism allows for seamless operation, enabling efficient control of liquids and gases in various applications.

Understanding how a swing valve works is essential for professionals in industries ranging from manufacturing to wastewater treatment. Its design not only minimizes pressure drops but also ensures a tight seal, ultimately enhancing the system's overall performance. In this article, we will explore the fundamental principles behind swing valves, their operational characteristics, and the pivotal role they play in maintaining fluid dynamics within complex systems. By examining the functionality and advantages of swing valves, we aim to highlight their importance in achieving optimal fluid control.

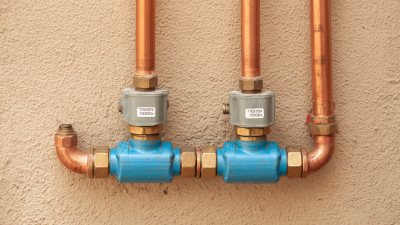

A swing valve is a type of valve that operates using a disc or flap that pivots on a hinge, allowing fluid to flow in one direction while preventing backflow. This mechanism is particularly effective in systems where gravity or pressure drives the fluid, making swing valves ideal for applications such as wastewater treatment, piping systems, and drainage systems. Unlike other types of valves, swing valves have no mechanical components like springs or gears, which contributes to their reliability and low maintenance needs.

In fluid control systems, swing valves function by responding to changes in fluid dynamics. When the flow of fluid reaches a certain pressure threshold, the disc swings open, permitting the liquid to pass through. As pressure decreases or reverses, the disc returns to a closed position, thereby sealing the system and stopping any unwanted backflow. This simple yet effective design makes swing valves popular in various industries, ensuring efficient and reliable control of fluid flow while minimizing potential leaks and system failures.

| Dimension | Details |

|---|---|

| Definition | A swing valve is a type of valve that uses a hinged disk to control fluid flow through a pipeline. |

| Operating Principle | The disk swings on a hinge, allowing for a tight seal when closed and facilitating flow when open. |

| Applications | Used in water supply systems, sewage treatment, and industrial fluid transport. |

| Advantages | Provides minimal pressure drop, efficient sealing, and low maintenance. |

| Disadvantages | May not provide as precise flow control as other valve types, such as globe valves. |

| Materials | Common materials include brass, stainless steel, and PVC depending on application needs. |

| Installation Considerations | Must be installed with the disk oriented horizontally to ensure proper operation. |

Swing valves are integral components in fluid control systems, characterized by their unique mechanism that allows for effective regulation of fluid flow. The mechanics of swaying motion in swing valves involve a disk or flap that pivots around a horizontal axis within a body. When fluid pressure is applied, the disk swings open, allowing flow through the valve. As the pressure decreases, the disk returns to a closed position due to its gravitational force, providing a tight seal that prevents backflow. Notably, this design enables a low-pressure drop across the valve, making it suitable for various industrial applications.

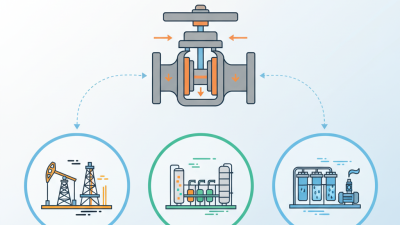

In fluid control systems, swing valves are particularly favored in high-flow scenarios due to their ability to handle large volumes of fluid with minimal resistance. According to a report by the Global Fluid Control Systems Market, the demand for swing valves is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2022 to 2030. This growth is driven by their reliability and efficiency in industries such as water treatment, oil and gas, and chemical processing. Furthermore, the simplistic design of swing valves minimizes maintenance requirements, thus reducing operational costs while ensuring optimal performance.

The swaying motion of a swing valve is not only pivotal for functionality but also influences its selection based on specific operational criteria. The angle and speed of the disk's movement can be adjusted depending on the application's requirements, aiding in precise flow control. As industries continue to seek more efficient fluid management solutions, swing valves are likely to play an increasingly significant role in advancing fluid control technology.

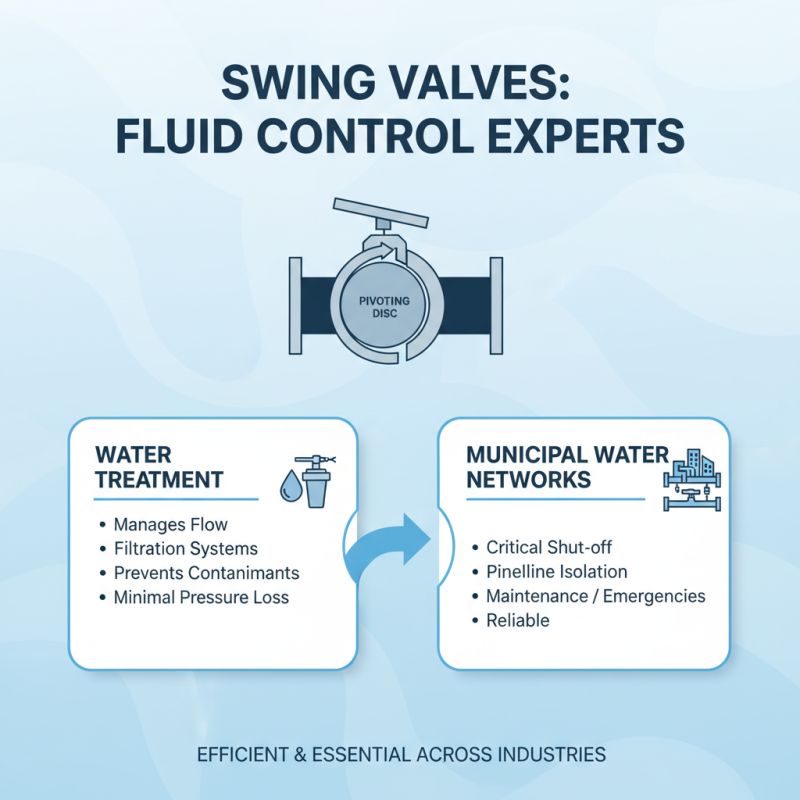

Swing valves are versatile components employed across various industries due to their efficient fluid control capabilities. In the water treatment sector, for example, swing valves are utilized to manage the flow of water in filtration systems, ensuring that the water remains free from contaminants. Their design allows for minimal pressure loss, which helps maintain optimal operational efficiency during the treatment process. Additionally, in municipal water distribution networks, swing valves function as critical shut-off tools, providing reliable isolation of sections of the pipeline for maintenance or emergencies.

In the oil and gas industry, swing valves play a vital role in controlling the flow of fluids through pipelines. They are commonly used for their ability to provide a tight seal when closed, preventing leaks and ensuring safety in transporting hazardous materials. Furthermore, in power generation plants, these valves are essential for regulating the flow of steam and water in cooling systems, contributing to enhanced efficiency and reliability. Overall, the adaptability of swing valves enables their integration in diverse applications, highlighting their importance in maintaining operational integrity across multiple sectors.

Swing valves play a crucial role in fluid control systems, offering several benefits that enhance operational efficiency. One of the primary advantages of swing valves is their simple design, which allows for easy installation and maintenance. They are known for their ability to handle a wide range of fluid types, making them versatile for various applications. Additionally, swing valves are less prone to wear and tear compared to other valve types, significantly extending their lifespan. Their lightweight nature also means that they can be subjected to lower operational forces, minimizing the energy needed to operate them.

However, swing valves do have limitations that should be considerations in their application. One significant drawback is that they are not well-suited for throttling applications; instead, they function best in fully open or fully closed positions. This characteristic can restrict their use in systems requiring precise flow control. Moreover, swing valves can exhibit a relatively slow response time compared to other valve types, which may affect system performance in dynamic applications. Lastly, their design may lead to pressure loss in some cases, as the valve’s disc can impede flow when in the open position. Understanding these benefits and limitations is crucial for effectively implementing swing valves in fluid control systems.

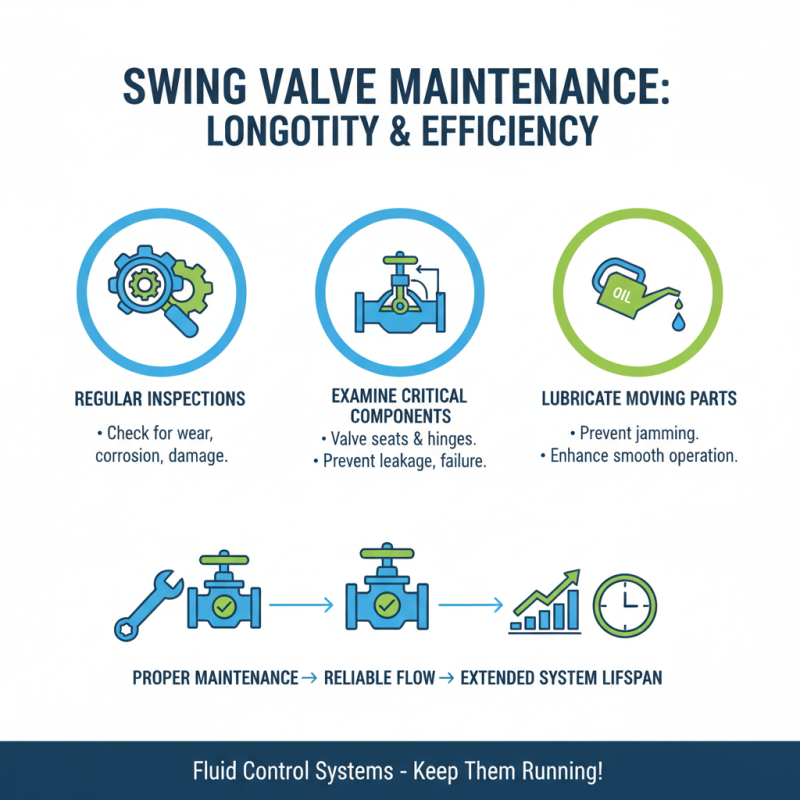

Maintaining swing valves is crucial for ensuring the longevity and efficiency of fluid control systems. Regular inspections should be conducted to check for any signs of wear, corrosion, or damage. It is essential to examine the valve seats and hinges, as these components experience significant stress and can lead to leakage or operational failure if not properly maintained. Lubricating moving parts can also prevent jamming and enhance the smooth operation of the valve.

Troubleshooting swing valves involves specific processes to identify and rectify issues swiftly. If a swing valve fails to close properly, it may indicate a buildup of debris or a malfunctioning hinge. Cleaning the valve and its surroundings can often resolve this issue. In instances of continued leakage, replacing worn seals or gaskets may be necessary. For more complex problems, assessing the valve's alignment within the system and ensuring that it is properly supported can help diagnose structural issues that might be affecting its performance. Regular training for personnel on these maintenance and troubleshooting protocols is vital for the effective management of swing valves in fluid control systems.