In the intricate world of fluid dynamics, the efficiency and reliability of industrial processes hinge significantly on the proper management of pressure within systems. At the heart of this management lie pressure control valves, essential components that regulate pressure levels, ensuring optimal performance across various applications.

This ultimate guide aims to demystify the complexities surrounding pressure control valves, shedding light on their functionalities, selection criteria, and maintenance strategies. Whether you're a seasoned engineer or a newcomer to the field, understanding how to master these critical devices can lead to enhanced system efficiency, reduced operational costs, and prolonged equipment lifespan.

Join us as we explore the key principles and best practices in mastering pressure control valves, empowering you to optimize your operations and achieve unparalleled performance.

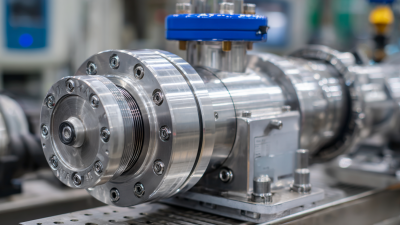

The evolution of pressure control valve technology has significantly transformed industrial applications, particularly in hydraulic fluid power systems. These systems are crucial in sectors such as transportation, heavy industry, and robotics, where precise control of fluid flow and pressure is essential for optimal performance. Over the years, advancements in materials and design have led to the development of more reliable and efficient pressure control valves, which not only enhance system safety but also improve operational efficiency.

Recent market trends indicate a growing demand for pressure safety valves, with projections suggesting a substantial increase in market size over the next decade. As industries strive for greater efficiencies and adherence to safety regulations, the role of sophisticated pressure control technologies becomes increasingly important. Innovations such as smart pressure sensors and automated control systems are paving the way for real-time monitoring and adjustment, thereby ensuring that pressure control valves operate within optimal parameters. This shift not only enhances safety but also contributes to energy savings and reduced operational costs in various industrial processes.

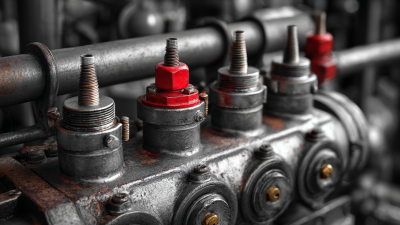

Pressure control valves (PCVs) are critical components in various industries, ensuring optimal performance and efficiency in fluid systems. The performance of these valves can be significantly influenced by several key factors. A report by the International Society of Automation indicates that improper sizing of pressure control valves can lead to efficiency losses of up to 20%. Accurate sizing ensures the valve can handle the system's flow requirements without unnecessary pressure drops or turbulence, which can compromise system integrity.

Material selection also plays a vital role in the performance of pressure control valves. According to a study published by the American Society of Mechanical Engineers, up to 30% of valve-related failures are attributed to corrosion and material wear due to aggressive fluids. Choosing the right materials, such as stainless steel or specialized alloys, can greatly enhance the lifespan and reliability of these valves in harsh environments. Furthermore, proper installation and maintenance practices are essential; the same study found that regular maintenance could improve valve performance by as much as 15%, highlighting the importance of proactive strategies in managing pressure control systems.

When it comes to designing pressure control valves, understanding industry standards and regulations is crucial for ensuring optimal performance and safety in various applications. Regulatory bodies such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) set forth guidelines that influence the design, testing, and certification processes for these critical components. Adhering to these standards helps manufacturers ensure that their valves can withstand specific pressure ranges and operational conditions, minimizing the risk of failures and accidents.

Furthermore, compliance with standards not only enhances product reliability but also fosters industry-wide best practices. For instance, standards may dictate material selection, pressure ratings, and performance testing protocols, which directly affect the durability and efficiency of pressure control valves. As industries evolve and new technologies emerge, regulations are regularly updated to reflect contemporary safety and performance needs. Therefore, staying informed about these changes is vital for engineers and manufacturers aiming to achieve superior valve performance while meeting legal and safety requirements.

| Dimension | Measurement | Industry Standard | Regulation Body |

|---|---|---|---|

| Max Operating Pressure | 3000 psi | ASME B31.3 | American Society of Mechanical Engineers |

| Flow Coefficient (Cv) | 1.5 | API 526 | American Petroleum Institute |

| Temperature Rating | -20°F to 350°F | ANSI/ISA 12.27.01 | International Society for Automation |

| Material Specification | Carbon Steel | ASTM A216 | American Society for Testing and Materials |

| Leakage Rate | Class VI | ANSI/FCI 70-2 | Fluid Controls Institute |

The advent of smart technology is revolutionizing the landscape of pressure control valves, making them more efficient and easier to integrate into automated systems. Smart pressure control valves not only provide enhanced precision in pressure management but also offer advanced monitoring capabilities. By utilizing IoT technology, these valves can relay real-time data, enabling operators to make informed decisions and reduce downtime.

Pressure control valves (PCVs) play a crucial role in various industrial applications, ensuring safety and efficiency by regulating pressure levels within systems. A recent industry report highlights that effective pressure control can lead to a reduction in operational costs by approximately 15%, emphasizing the importance of proper valve selection and implementation. Case studies reveal that in the oil and gas sector, PCVs significantly mitigate risks associated with pressure fluctuations during drilling operations, illustrating their real-world importance.

When selecting a pressure control valve, consider factors such as media type, temperature, and expected pressure ranges. According to the Flow Control Magazine, maintaining optimal pressure can increase equipment lifespan by up to 20%. A diligent approach to maintenance, including regular inspections and recalibrations, will ensure that your valves function smoothly, preventing costly downtimes and operational inefficiencies.

For enhanced performance, ensure that your PCV system is compatible with advanced monitoring technologies. Integrating IoT solutions can provide real-time data, allowing for more precise control and immediate adjustments to pressure levels. As highlighted in a recent study from the American Society of Mechanical Engineers, companies utilizing smart valves report a 30% increase in processing efficiency.