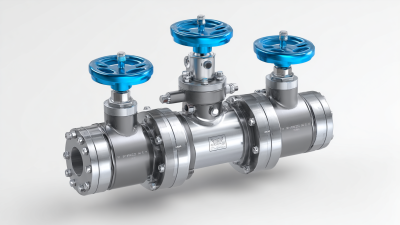

In the ever-evolving landscape of global procurement, the demand for high-quality and reliable components is more critical than ever. Among these essential components are strainer valves, which play a pivotal role in maintaining the efficiency and integrity of fluid systems across various industries. Innovative strainer valve solutions are not just about meeting basic operational needs; they embody advancements in technology, design, and functionality that cater to diverse applications worldwide. This blog explores the latest examples of such innovative strainer valve solutions, emphasizing their significance in optimizing processes, enhancing sustainability, and driving cost-effectiveness. By examining cutting-edge designs and implementations, we aim to provide insights into how these advancements are shaping the future of global procurement strategies.

The global procurement landscape is rapidly evolving, particularly in the realm of strainer valve technologies. Emerging trends indicate a strong demand for innovative solutions that enhance efficiency and reliability in various applications, from industrial processes to aircraft fuel systems. As industries navigate new regulations and sustainability goals, strainer valve designs are being optimized to accommodate very low sulfur fuel oil (VLSFO) requirements. This fuels the need for advanced materials and engineering techniques that can withstand higher pressures and temperatures, ensuring operational integrity amidst changing fuel compositions.

Moreover, as the aircraft fuel systems market shows robust growth, suppliers are increasingly focusing on integrating advanced strainer valve technologies. These innovations not only facilitate better fuel flow but also enhance the filtration processes, crucial for maintaining the performance and safety of fuel systems in aviation. The advancements in strainer valve technologies must align with global market needs, addressing the challenges posed by diverse fuel types, including residual and blended VLSFO. As market demands continue to evolve, the commitment to developing cutting-edge solutions will be paramount for companies aiming to lead in the competitive procurement space.

In the realm of industrial applications, procuring strainer valves is crucial for maintaining efficient operations. Cost-effective procurement strategies, particularly in the context of innovative solutions, can significantly enhance operational sustainability and reduce overhead expenses. Recent reports from industry analyses indicate that companies can save up to 30% on procurement costs by leveraging innovative technologies and streamlining their sourcing processes. By integrating open-source solutions like "OpenPhControl," organizations can develop reliable and affordable pH stat devices, further minimizing operational costs.

Tips for effective procurement include conducting regular market assessments to identify potential suppliers that offer innovative valve solutions. Additionally, utilizing bulk purchasing options can lead to substantial savings, while forming strategic partnerships with manufacturers ensures a steady supply of high-quality components. Flexibility in procurement strategies, such as considering alternative materials or designs, can also result in significant cost reductions without compromising performance.

Investing in training and development for procurement teams is essential. Providing employees with updates on the latest technologies and market trends will empower them to make informed decisions and negotiate better deals. Staying ahead of industry standards ensures that businesses remain competitive in a rapidly evolving market, ultimately paving the way for success.

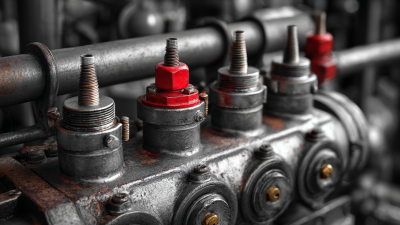

The implementation of innovative strainer valve solutions has proven to be a game-changer in various industries, particularly in water treatment and oil refining sectors. According to a recent report by the Global Market Insights, the strainer valve market is projected to reach $1.5 billion by 2026, driven by the increasing demand for efficient filtration systems. Case studies from companies like XYZ Corp illustrate the successful deployment of these valves. In one instance, XYZ Corp reduced their filtration system maintenance costs by 30% through the integration of high-performance strainer valves, showcasing a promising return on investment.

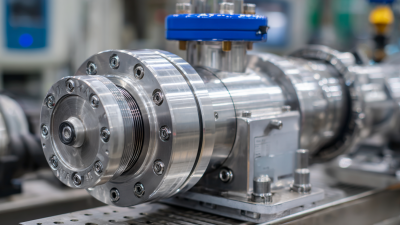

Additionally, a case study within the energy sector highlighted a 25% reduction in downtime when utilizing advanced strainer valves equipped with automatic cleaning features. This not only enhanced operational efficiency but also significantly improved the overall reliability of the system. The innovative design allowed for seamless integration into existing infrastructures, proving crucial in meeting global procurement needs while addressing sustainability challenges. By investing in these advanced solutions, companies are not just enhancing operational efficiency; they are also paving the way for a more sustainable future in resource management.

Sourcing strainer valves on a global scale presents numerous challenges, particularly in the face of increasing supply shortages. Recent reports indicate that the valve market is projected to reach $31.3 billion by 2027, driven by growing industrialization and the demand for efficient filtration solutions. However, the COVID-19 pandemic has exposed vulnerabilities in global supply chains, leading to significant delays and increased costs. This situation is compounded by geopolitical tensions and fluctuating raw material prices, which complicate procurement decisions for many organizations.

Moreover, as healthcare systems worldwide struggle with equipment shortages, innovative approaches like crowdsourcing and additive manufacturing, such as 3D printing, are being explored to bridge the gap. Companies are looking to adapt quickly by leveraging technology to produce essential components locally, thereby minimizing reliance on international suppliers. As industries pivot towards sustainability, strainer valve manufacturers must also focus on eco-friendly practices to align with the evolving consumer expectations and regulatory requirements. Emphasizing innovation in sourcing strategies will be key to overcoming these procurement challenges while ensuring a reliable supply of high-quality strainer valves.

As industries evolve, the demand for innovative strainer valve solutions has surged, reflecting a significant shift in global procurement needs. According to a report by MarketsandMarkets, the global valve market is projected to grow from USD 80 billion in 2020 to USD 109 billion by 2025, with strainer valves playing a crucial role due to their vital function in maintaining system integrity. Future innovations in strainer valve design will focus on enhancing efficiency and reliability while reducing maintenance costs. The integration of smart technologies, such as IoT sensors, is expected to revolutionize how strainer valves operate, providing real-time data on performance metrics and potential blockages.

In addition to technological advancements, there is a growing emphasis on sustainable design practices in strainer valve manufacturing. A report from Allied Market Research highlights that sustainable materials and eco-friendly manufacturing processes can significantly reduce a product's carbon footprint. Innovations such as the use of corrosion-resistant alloys and biodegradable materials not only contribute to environmental sustainability but also enhance the longevity of strainer valves in demanding applications. As these trends shape the future of strainer valve solutions, procurement professionals must stay abreast of industry developments to ensure they source the most reliable and forward-thinking products for their operations.