Selecting the appropriate pressure relief valve is crucial for ensuring the safety and efficiency of any pressure system. According to a report by the International Society for Pharmaceutical Engineering, equipment failures due to inappropriate valve selection can lead to costly downtime, with average losses ranging from $100,000 to $1 million per incident. Furthermore, the American Society of Mechanical Engineers highlights that poorly chosen pressure relief valves can result in catastrophic failures, risking both personnel safety and environmental integrity. With a growing emphasis on regulatory compliance and operational reliability, understanding the key factors involved in choosing the right pressure relief valve is essential for engineers and system designers alike. This guide aims to provide seven essential tips to navigate the complexities of valve selection, ensuring optimal performance and safety in your systems.

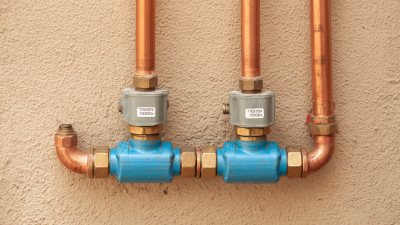

When selecting the right pressure relief valve for your system, it is crucial to identify the specific requirements of your application. Different systems, whether they're in manufacturing, chemical processing, or water treatment, have unique characteristics that influence valve specifications. Factors such as operating pressure, temperature, and the type of media involved must be precisely assessed. A study from the American Society of Mechanical Engineers highlights that improperly selected pressure relief valves can lead to significant operational disruptions and safety hazards, costing industries millions in downtime and compliance failures.

Moreover, as industries increasingly adopt integrated risk management strategies, understanding the environment in which your relief valve operates becomes even more critical. Enterprise Risk Management (ERM) emphasizes the importance of a holistic view of all operational risks, including those associated with malfunctioning safety equipment. According to the National Fire Protection Association, nearly 40% of industrial accidents are tied to equipment failure, underscoring the importance of selecting valves that meet stringent safety standards and reliability metrics. Therefore, clearly defining the operational parameters of your system is not just a best practice but a vital step in ensuring both safety and efficiency.

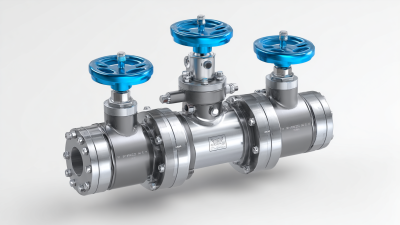

When choosing the right pressure relief valve (PRV) for your system, it's crucial to understand the different types available to ensure operational safety and efficiency. Pressure relief valves can be categorized primarily into two types: spring-loaded and pilot-operated valves. Spring-loaded valves are widely used due to their simple design and reliability, making them suitable for various applications. On the other hand, pilot-operated valves offer enhanced performance for high-pressure and varied flow conditions, making them ideal for systems requiring precise pressure control.

Recent advancements in PRV technology further emphasize the importance of selecting the correct type. For instance, new high-pressure relief valves have been introduced to improve reliability in storage tanks, reflecting the need for enhanced safety measures in various industries. Additionally, studies indicate that the type of safety valve can significantly influence the safety and operational efficiency of systems, such as in gas processing plants and applications involving lithium-ion batteries. Understanding the characteristics and functionalities of these different types of pressure relief valves can help engineers and operators make informed decisions tailored to their specific needs.

When selecting a pressure relief valve, material compatibility plays a crucial role in ensuring the longevity and efficiency of your system. Industries increasingly rely on advanced materials such as indium tin oxide (ITO), silver nanowires, and carbon nanotubes to enhance the performance of pressure relief valves. These materials offer unique properties that can withstand various environmental conditions and prevent corrosion, which is especially important in applications ranging from consumer electronics to automation systems.

According to recent market analyses, the organic photonic and electronic devices sector is experiencing significant growth, with organic photoelectrochemical transistors (OPECTs) emerging as a groundbreaking technology. OPECTs, developed by a collaborative team from prominent research institutions, exemplify the trends towards adopting innovative materials in device manufacturing. As these advanced materials become more prevalent, understanding their compatibility with various fluids and pressures is essential. Reports suggest that the global natural refrigerant market is projected to reach $259.8 million by 2022, growing at a compound annual growth rate (CAGR) of 6.5% through 2030. The integration of such materials into pressure relief systems is vital for the optimization of performance in dynamic applications, reflecting a growing emphasis on sustainable and efficient industrial solutions.

When selecting the appropriate pressure relief valve (PRV) for your system, determining the correct sizing and set pressure parameters is crucial for ensuring safety and efficiency. According to a report by the American Society of Mechanical Engineers (ASME), improper sizing can lead to frequent valve operations, potentially causing fatigue and premature failure, which can result in costly downtime or catastrophic failures. A PRV must be sized to accommodate the maximum flow rate, which is often dictated by the system’s specific fluid dynamics and operating conditions. It is recommended to conduct a thorough analysis using methodologies such as the "Orifice Flow Equation" to calculate the required flow capacity accurately.

Setting the right pressure parameters is equally important. The set pressure of a valve determines when it will open to relieve excess pressure, safeguarding downstream equipment. A study published by the Pressure Relief Device Subcommittee indicates that setting the valve at too high a pressure may compromise system safety, while setting it too low can lead to nuisance tripping. Generally, it is advisable for the set pressure to be based on the Maximum Allowable Working Pressure (MAWP) of the system, allowing a margin for fluctuations. Consulting industry standards and professional guidelines, such as those provided by the National Board of Boiler and Pressure Vessel Inspectors, can further aid in establishing these critical metrics effectively.

| Dimension | Value |

|---|---|

| Pipe Size | 2 inches |

| Set Pressure | 50 psi |

| Design Flow Rate | 30 GPM |

| Operating Temperature | 150°F |

| Fluid Type | Water |

| Material | Stainless Steel |

| Connection Type | Flanged |

When selecting a pressure relief valve for your system, understanding regulatory compliance and industry standards is crucial. The regulatory landscape is continually evolving, requiring organizations to stay informed about the latest laws and requirements. For instance, a recent study noted that non-compliance can result in financial penalties up to 4% of total annual revenue for large corporations, highlighting the significant economic impact of regulatory adherence. Thus, identifying a pressure relief valve that meets both local and international standards, such as API or ASME, is essential to mitigate risks and ensure safety.

In addition, organizations must consider the changing tides of technology and its implications for compliance. With the rise of artificial intelligence in industrial applications, compliance frameworks are adapting accordingly. Reports indicate that companies leveraging AI are facing mounting pressure to comply with evolving regulations related to safety and operational standards. Establishing a robust compliance program that not only aligns with existing regulatory frameworks but also anticipates future changes can prove vital in maintaining operational integrity and fostering business growth. Adopting such proactive measures is essential for navigating the complexities of today’s compliance landscape.