In today's rapidly evolving industrial landscape, the role of sight glass valves has become increasingly prominent across various sectors, significantly enhancing operational efficiency and safety. According to a recent market research report by Mordor Intelligence, the global sight glasses market is projected to grow at a CAGR of 5.2% from 2022 to 2027, driven by the rising demand for effective visual monitoring in industries such as water treatment, food and beverage, and chemical processing. These valves not only facilitate the observation of fluid flow and conditions but also contribute to better process control and maintenance strategies. By integrating sight glass valves into their systems, industries can optimize their operations and ensure a higher standard of quality and safety. This ultimate guide explores the creative applications of sight glass valves, shedding light on their benefits and versatility in diverse industrial settings.

The food and beverage industry is increasingly adopting sight glass valves for their ability to enhance operational efficiency and product quality. These transparent valves allow operators to monitor fluid levels, flow rates, and even the clarity of the contents without interrupting the process. According to a report by MarketsandMarkets, the global sight glass market is projected to reach $1.2 billion by 2025, with significant contributions from the food and beverage sector. The ability to visually inspect processes in real-time helps in reducing waste and improving quality control, which is vital in maintaining regulatory compliance.

Innovative applications of sight glass valves are evident in various stages of food production. For instance, in beverage manufacturing, sight glasses can be integrated into brewing equipment to monitor the fermentation process. This capability enables brewers to adjust parameters on-the-fly, ensuring optimal flavor profiles and consistency. Furthermore, in dairy processing, sight glass valves permit constant monitoring in pasteurization systems, crucial for maintaining product safety and quality. A study by the Dairy Optimization Institute revealed that real-time monitoring with sight glass technology could reduce milk spoilage rates by up to 20%, showcasing the impact of this innovation in the industry.

| Application | Industry | Benefits | Materials Used |

|---|---|---|---|

| Monitoring Liquid Levels | Food & Beverage | Ensures consistency in production | Stainless Steel, Glass |

| Batch Visibility | Brewery | Improves quality control processes | Borosilicate Glass, PVC |

| Flow Monitoring | Juice Processing | Enhances operational efficiency | Polypropylene, PTFE |

| Inspection of Contents | Dairy Production | Identifies contamination risks | Stainless Steel, Glass |

| Pressure Relief | Soft Drink Industry | Prevents accidents and enhances safety | 316 Stainless Steel, Acrylic |

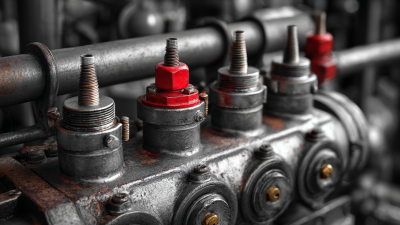

In the chemical industry, the importance of safety cannot be overstated. Sight glass valves play a crucial role in enhancing operational safety by providing a transparent view of the flow and status of fluid processes. According to a report by the Occupational Safety and Health Administration (OSHA), improper monitoring of fluid levels can lead to catastrophic failures, resulting in both severe financial loss and risks to employee safety. By integrating sight glass valves into chemical systems, operators can detect abnormalities early, thereby preventing potential hazards.

Tips for effective use of sight glass valves include ensuring regular maintenance and inspection. It’s essential to keep the glass clean and free from residues that can obstruct visibility, as recommended by the American Chemical Society. Additionally, using valves that are designed to withstand high pressure and temperatures can further enhance safety. Data from the Chemical Safety Board underscores that facilities with robust monitoring systems, including sight glasses, experience significantly fewer accidents—up to 30% reduction in incidents when proper visibility is maintained.

Furthermore, training employees on the importance of sight glass valves can have a profound impact on the overall safety culture within a plant. Regular training sessions ensure that staff understand how to interpret visual indicators properly, contributing to prompt and informed decision-making when dealing with potential leaks or changes in fluid dynamics. Implementing these practices will not only enhance safety but also improve overall operational efficiency in the chemical industry.

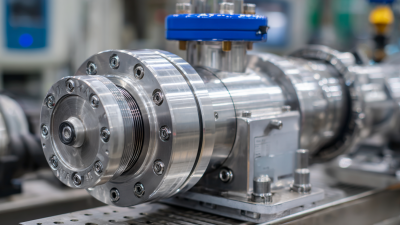

Sight glass valves play a pivotal role in enhancing efficiency and monitoring within HVAC systems. These transparent components allow technicians to easily observe the flow of refrigerants and identify any potential issues, such as bubbles or discoloration, which can indicate system inefficiencies or leaks. By providing real-time visual feedback, sight glass valves help maintain optimal refrigerant levels and ensure that systems operate at peak performance.

Sight glass valves play a pivotal role in enhancing efficiency and monitoring within HVAC systems. These transparent components allow technicians to easily observe the flow of refrigerants and identify any potential issues, such as bubbles or discoloration, which can indicate system inefficiencies or leaks. By providing real-time visual feedback, sight glass valves help maintain optimal refrigerant levels and ensure that systems operate at peak performance.

Tips for Utilizing Sight Glass Valves:

In the pharmaceutical manufacturing sector, custom sight glass solutions play a critical role in ensuring quality and compliance throughout production processes. These specialized valves allow for real-time monitoring of fluid levels and conditions, which is paramount in maintaining the integrity of sensitive pharmaceutical formulations. As companies strive to enhance their manufacturing capabilities, incorporating tailored sight glass systems can significantly improve operational efficiency and safety.

Tips for Implementing Custom Sight Glass Solutions:

Sight glass valves play a critical role in wastewater treatment processes by providing a visual inspection point for operators. These valves allow for real-time monitoring of liquid flow and clarity without interrupting the system. As wastewater passes through treatment stages, sight glass valves enable operators to assess the effectiveness of the treatment, ensuring contaminants are being adequately removed. This capability enhances operational efficiency and improves safety by allowing for early detection of issues before they escalate.

In addition to monitoring clarity, sight glass valves can be utilized to observe sedimentation processes and identify any blockages in the system. Their transparent structure allows for instant visibility, aiding in decision-making and timely interventions. By integrating sight glass valves into wastewater treatment systems, facilities can achieve higher standards of compliance and environmental protection while also reducing downtime caused by unexpected maintenance issues. This innovative application demonstrates how these seemingly simple components contribute to the overall effectiveness of wastewater management.

This bar chart illustrates the efficiency percentages of sight glass valves in different stages of wastewater treatment processes. These stages include Initial, Secondary, Tertiary treatments, Sludge Processing, and Disinfection. As shown, the highest efficiency is observed during Disinfection, highlighting the critical role sight glass valves play in ensuring effective wastewater management.