In the realm of fluid control and safety, the significance of double check valves cannot be overstated. According to a report from Global Market Insights, the global double check valve market is projected to surpass USD 1 billion by 2026, driven by the rising demand for reliable backflow prevention solutions across various industries. Double check valves are essential in protecting potable water supplies from contamination, ensuring that no reverse flow occurs under any circumstances. However, despite their critical role, many global buyers encounter common issues related to their maintenance and installation, which can lead to significant operational challenges. This comprehensive guide aims to illuminate the frequent problems faced by users of double check valves and provide actionable insights to enhance their performance and longevity in diverse applications.

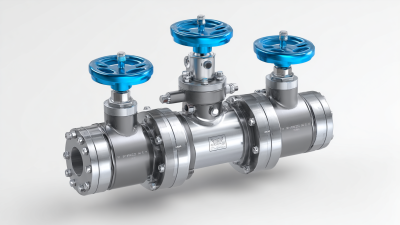

Understanding the functionality and benefits of double check valves is crucial for global buyers looking to optimize their systems. Double check valves serve a vital role in backflow prevention, ensuring that fluids flow in a single direction and protecting water supplies from contamination. Their reliability in various applications, from industrial processes to residential plumbing, makes them an essential component in maintaining system integrity and safety.

**Tips:** When selecting a double check valve, it's important to consider the flow rate and pressure requirements of your specific application. Ensuring compatibility with existing piping systems will prevent issues during installation and operation. Furthermore, look for valves that are certified to meet local regulations and standards, guaranteeing quality and performance.

Additionally, ongoing maintenance is key to the longevity of double check valves. Regular inspections can help identify potential wear and tear before they lead to system failures. Ensure that you have a maintenance plan in place, including the timely replacement of worn components, to keep your systems running efficiently.

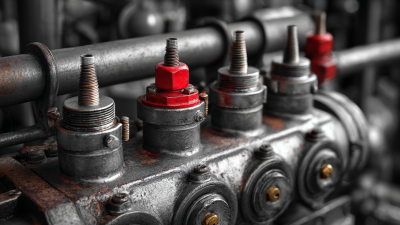

Double check valves are essential components in many plumbing systems, ensuring that backflow does not occur and maintaining the integrity of water supply. However, like any mechanical device, they can encounter issues that can compromise their function. Common problems faced by double check valves include leakage, improper sealing, and wear and tear due to environmental factors. These issues often stem from factors such as poor installation, lack of maintenance, or the use of inferior materials.

To mitigate these problems, regular inspection and maintenance should be prioritized. Ensuring proper installation by qualified professionals can prevent misalignment and leaks. Additionally, using high-quality materials tailored for the specific application can greatly enhance the durability and efficiency of the valves.

Tips for preventing issues include routinely checking the valve for any signs of wear and maintaining clean surroundings to prevent debris buildup. Installing strainers or filters can also help protect the valve from contaminants that may cause wear. By addressing these common problems proactively, buyers can prolong the lifespan and functionality of their double check valves, ultimately leading to a more reliable plumbing system.

| Issue | Description | Possible Causes | Solutions |

|---|---|---|---|

| Leakage | Fluid leaks from the valve during operation. | Worn seals or improper installation. | Inspect and replace seals; ensure correct installation. |

| Pressure Drop | Unwanted drop in system pressure. | Blockages or incorrect sizing of valves. | Check for blockages; consider valve size adjustments. |

| Noise | Unusual sounds during operation. | Cavitation or turbulence within the valve. | Adjust flow rates; check for proper valve selection. |

| Operational Failure | Valve fails to open or close properly. | Debris accumulation or mechanical faults. | Clean the valve; inspect for mechanical damage. |

| Corrosion | Deterioration of the valve material. | Exposure to corrosive fluids or environments. | Use corrosion-resistant materials; regular maintenance checks. |

Double check valves are essential components in many plumbing and industrial systems, ensuring that fluids flow in the correct direction while preventing backflow. However, maintaining their optimal performance can be a challenge. According to the American Society of Mechanical Engineers (ASME), improper maintenance leads to about 30% of all valve failures, significantly impacting system efficiency and safety.

To maintain double check valve performance, regular inspections and proactive maintenance are key. It's recommended to check the valves at least twice a year, looking for signs of wear, leaks, or corrosion. A study by the International Association of Plumbing and Mechanical Officials (IAPMO) indicates that timely maintenance can reduce repair costs by up to 25%.

**Tip:** Always replace worn gaskets or seals with manufacturer-approved parts to ensure a proper fit. Furthermore, conducting flow tests can help identify issues early, allowing for swift corrective measures that protect system integrity. By following these practical solutions, global buyers can maximize the lifespan and reliability of their double check valves.

When selecting the right double check valve for a specific application, it’s imperative to understand the unique requirements that each industry may impose. According to a recent market analysis report by MarketsandMarkets, the global double check valve market is expected to reach USD 2.1 billion by 2025, driven by increasing water demand and stringent regulations on backflow prevention. In environments such as residential plumbing, fire protection systems, and irrigation, the choice of valve significantly impacts both efficiency and safety.

For instance, materials such as brass and stainless steel are commonly preferred due to their durability and resistance to corrosion. Per a study published by the American Society of Plumbing Engineers, valves made from these materials can extend lifespan by up to 30%, depending on application conditions. Moreover, selecting a valve with the appropriate flow rate is vital; an improperly matched valve can result in inefficiencies and increased operational costs. Industry experts recommend detailed assessments of pressure requirements and installation environments to ensure that the double check valve chosen aligns perfectly with specific application needs.

When considering the purchase of double check valves, global buyers must pay close attention to several key factors to ensure optimal performance and compliance with regional standards. First, it is essential to understand the specific application for which the valve will be used. Whether in water supply systems, fire protection, or industrial processes, the selection of materials, sizes, and pressure ratings must be compatible with the working environment to prevent leaks or failures.

Another vital consideration is the certification and compliance of the valves with local and international standards. Buyers should verify that the products meet relevant regulations, such as those set forth by the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO). This not only ensures safety and reliability but also influences the product's overall lifespan and maintenance requirements. Additionally, examining the manufacturer’s reputation and customer support services can aid in making an informed decision, as long-term operation may necessitate technical assistance or replacement parts.

This bar chart represents the percentage of common issues faced by global buyers when purchasing double check valves. The data illustrates the challenges in terms of quality, compatibility, maintenance requirements, cost, and availability.