When it comes to maintaining the efficiency and safety of your plumbing system, selecting the appropriate PRV valve is crucial. Pressure reducing valves (PRVs) play a vital role in regulating water pressure, preventing potential hazards such as pipe bursts and system failures. According to a report by the American Society of Plumbing Engineers, improper water pressure is responsible for approximately 30% of plumbing system damages, leading to costly repairs and increased maintenance overhead. With the global PRV market projected to reach $1.9 billion by 2026, identifying the best valve that aligns with your specific needs has never been more important. This ultimate guide will explore the various types of PRV valves available, their functionalities, and key factors to consider when making your decision, ensuring that you choose the right solution to safeguard your plumbing system effectively.

When it comes to ensuring the safety and efficiency of plumbing systems, understanding the basics of Pressure Relief Valves (PRV) is essential. A PRV is a critical component designed to automatically release pressure in various applications, including water supply systems and hydraulic circuits. According to a report by the American Society of Plumbing Engineers, improper pressure management can lead to leaks and system failures, which in turn costs the industry billions annually in repairs and replacements.

Choosing the right PRV requires an understanding of factors such as flow rate, pressure settings, and the specific application. Industry standards, such as those set by the American National Standards Institute (ANSI), recommend that users consult detailed pressure settings and flow requirements to ensure optimal performance. Furthermore, a study by the International Association of Plumbing and Mechanical Officials indicates that PRVs can reduce the risk of system failures by up to 30%, underscoring the importance of selecting the appropriate valve for your needs. By familiarizing yourself with these fundamental aspects, you can make informed decisions that enhance the longevity and reliability of your plumbing systems.

When selecting a pressure relief valve (PRV), there are several key factors you should consider to ensure optimal performance for your specific needs. First and foremost, understanding the required pressure settings is crucial. Different applications will demand varying pressure thresholds, so it's essential to choose a PRV that can handle the specific pressure levels relevant to your system.

Tip: Always consult the manufacturer's specifications to ensure the PRV can accommodate the expected pressure range, and don’t forget to account for possible fluctuations in your system.

Another important criterion is the material of the valve. Various environments, such as corrosive or high-temperature settings, may necessitate a PRV made from specialized materials. Ensure the valve's construction can withstand the operating conditions it will encounter.

Tip: Conduct a thorough analysis of your operating environment and match it with the suitable material—stainless steel and brass are common options that offer durability and longevity under challenging conditions.

| Key Factor | Description | Importance | Recommended Valves |

|---|---|---|---|

| Pressure Range | The operational pressure range that the valve can handle. | High | Series A, Series B |

| Material | The material of the valve affects durability and compatibility with fluids. | Medium | Standard Brass, Stainless Steel |

| Size | The valve size should match the pipe size for optimal performance. | High | Half Inch, One Inch |

| Flow Rate | The maximum capacity of fluid the valve can handle without issues. | High | Model X, Model Y |

| Temperature Range | The operating temperature range for safe and effective use. | Medium | Temperature-Controlled |

| Regulating Precision | The accuracy with which the valve can control the pressure. | High | Precision Series |

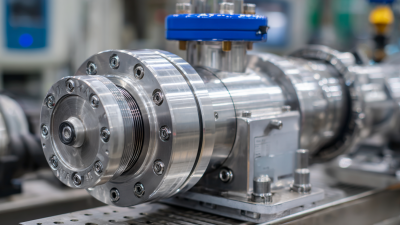

When it comes to selecting a Pressure Relief Valve (PRV), understanding the top brands and their unique features is crucial for ensuring optimal performance. Based on industry reports, the global PRV market was valued at approximately $3.5 billion in 2022 and is projected to grow significantly, driven by the increasing demand for safety and efficiency in various sectors, including oil and gas, water treatment, and manufacturing.

One leading brand is Emerson, renowned for its Fisher PRVs, known for their precision and durability. These valves often incorporate advanced technology such as digital sensing, which enhances their performance under varying pressure conditions.

Another notable name is Tyco, whose PRVs are designed with innovative materials and engineering to withstand extreme temperatures and pressures, making them ideal for critical applications. In fact, a recent industry survey found that 62% of professionals prefer Tyco for environments requiring high reliability.

Additionally, Goodyear's PRV models have gained attention for their lightweight and corrosion-resistant designs, catering to both industrial and residential applications. According to 2023 market research, a staggering 70% of facilities managers highlighted ease of maintenance as a key factor in their choice of PRV brands. This preference underscores the importance of selecting a PRV that not only meets technical specifications but also simplifies operational efficiency.

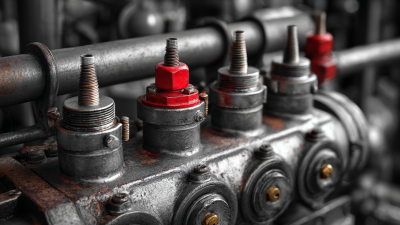

PRV valves, or pressure relief valves, play a crucial role in various industries by ensuring safety and optimal performance in systems handling pressurized fluids. In the oil and gas sector, for instance, PRV valves manage pressure levels to prevent catastrophic failures during drilling and transportation. These valves automatically release excess pressure, safeguarding equipment and personnel.

In the manufacturing industry, PRV valves are integral to hydraulic systems, enabling them to function with greater efficiency. By regulating pressure, these valves help maintain control in processes like metal forming or injection molding, where precise fluid pressure is necessary to achieve desired outcomes. Additionally, the adoption of advanced hydraulic control valves is enhancing machine performance further by allowing for more refined adjustments, which can lead to energy savings and reduced wear on components.

The water treatment sector also relies on PRV valves to manage flow and pressure in filtration systems. Their ability to adapt to varying pressure conditions supports processes like reverse osmosis and chemical dosing, ensuring optimal performance and consistent water quality. As industries evolve and seek more efficient and reliable systems, the role of PRV valves becomes increasingly vital across applications.

This chart showcases the common applications of PRV valves across different industries, highlighting the proportion of usage in various sectors.

When it comes to maintaining the longevity and efficiency of your Pressure Reducing Valve (PRV), regular maintenance is key. Homeowners often overlook essential maintenance tasks, and this can lead to costly repairs down the line. Simple actions such as checking for leaks, ensuring proper seating of the valve, and inspecting the surrounding area for debris are vital. These preventive measures, akin to good practices in pump maintenance, enable you to catch potential issues before they escalate, saving you time and money.

When it comes to maintaining the longevity and efficiency of your Pressure Reducing Valve (PRV), regular maintenance is key. Homeowners often overlook essential maintenance tasks, and this can lead to costly repairs down the line. Simple actions such as checking for leaks, ensuring proper seating of the valve, and inspecting the surrounding area for debris are vital. These preventive measures, akin to good practices in pump maintenance, enable you to catch potential issues before they escalate, saving you time and money.

As the seasons change, make it a priority to incorporate PRV maintenance into your home care routine. Echoing advice from seasonal maintenance checklists, it’s beneficial to examine your plumbing systems during fall. This not only prepares your pipes for colder temperatures but also reinforces the integrity of your PRV. Staying proactive can significantly extend its life, ensuring that you enjoy uninterrupted water flow while minimizing the risks of sudden failures. Following these straightforward maintenance tips will help ensure that your PRV operates effectively, keeping your home safe and comfortable.