In the industrial sector, the selection of the appropriate ball valve is critical to ensuring operational efficiency and safety. According to a report by MarketsandMarkets, the global ball valve market is projected to reach USD 14.88 billion by 2025, growing at a significant CAGR due to increasing applications across industries such as oil and gas, water and wastewater, and power generation.

The versatility of ball valves, known for their reliability and tight sealing capabilities, makes them a preferred choice for many industrial processes. Furthermore, a study from Research and Markets highlights that the demand for accurate flow control solutions is driving innovations in ball valve design and functionality. Therefore, understanding the essential criteria for selecting the right ball valve for your specific industrial needs is paramount for maximizing performance and minimizing maintenance costs.

The versatility of ball valves, known for their reliability and tight sealing capabilities, makes them a preferred choice for many industrial processes. Furthermore, a study from Research and Markets highlights that the demand for accurate flow control solutions is driving innovations in ball valve design and functionality. Therefore, understanding the essential criteria for selecting the right ball valve for your specific industrial needs is paramount for maximizing performance and minimizing maintenance costs.

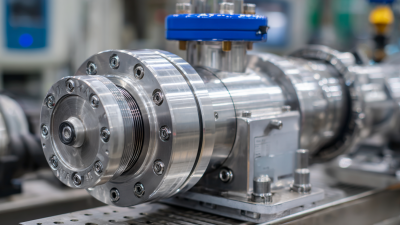

When selecting the right ball valve for industrial applications, it's crucial to understand the different types available, as each serves unique purposes and functionalities. The most common types include full-port, reduced-port, and V-ball valves. Full-port ball valves allow for unrestricted flow, making them ideal for applications where pressure drop needs to be minimized. In contrast, reduced-port options provide a more compact design, suitable for lower flow conditions while still maintaining good sealing properties.

Another critical factor to consider is the valve material, which greatly impacts durability and compatibility with various media. Common materials include brass, stainless steel, and plastic, each offering distinct advantages. For example, stainless steel ball valves are preferred in corrosive environments due to their resistance to oxidation and chemical reactions. Additionally, segment or V-ball valves have adjustable flow rates, making them suitable for throttling applications where precise control is necessary. Understanding these variations will enable industry professionals to select the most appropriate ball valve, ensuring optimal performance and longevity.

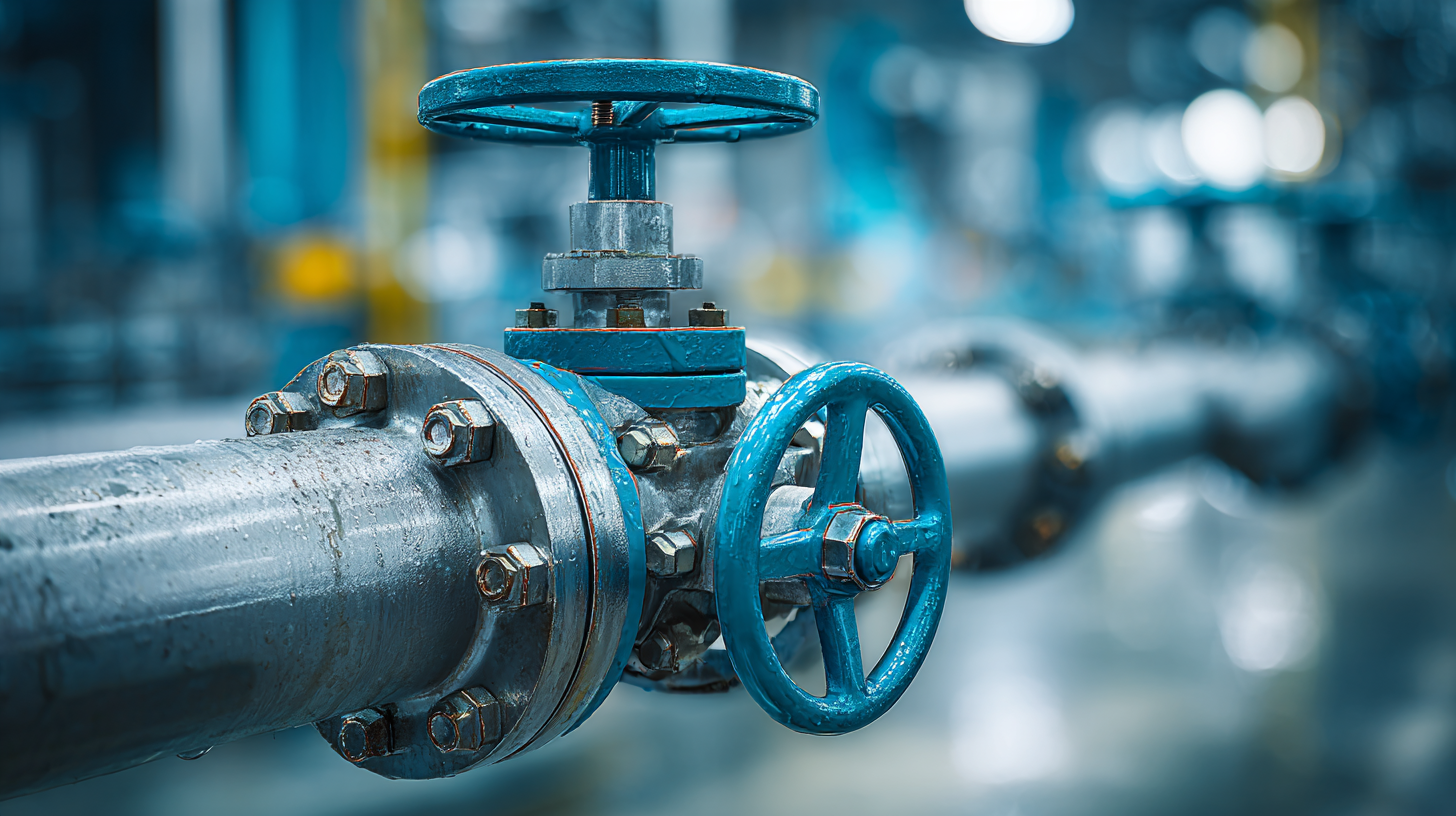

When selecting the right ball valve for industrial applications, understanding key performance metrics such as pressure, temperature, and flow rate is essential. The pressure rating of a valve determines its ability to withstand potential surges and operational demands. For instance, in high-pressure applications like hydrogen refueling stations, recent studies have indicated that valve designs with specific taper angles, such as 60°, can optimize decompression performance while minimizing temperature rises. This aspect is crucial because temperature fluctuations can significantly impact valve longevity and reliability.

Temperature ratings should also be carefully evaluated, especially in processes involving extreme heat or cold. Ensuring that the ball valve can operate within the desired temperature range helps to maintain operational integrity. Additionally, flow rate considerations will affect the valve's capacity to manage fluids effectively. Automated valve choices have also become pivotal, with options that facilitate precise control over flow rates being increasingly favored in industrial settings. By considering these metrics, engineers and procurement teams can make informed decisions that align with their operational requirements and enhance system performance.

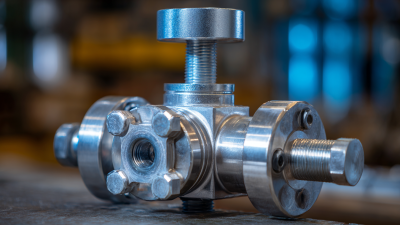

When selecting a ball valve for industrial applications, material choice plays a crucial role in ensuring durability and resistance to corrosion. Different environments expose valves to varying challenges; hence, the material must withstand factors such as temperature fluctuations, pressure variances, and chemical exposure. Common materials for ball valves include stainless steel, brass, and PVC, each offering distinct advantages. For instance, stainless steel is favored for its excellent strength and corrosion resistance, making it ideal for harsh environments.

**Tips:** Always consider the specific chemicals the valve will be exposed to; incompatible materials can lead to rapid degradation. Additionally, evaluating temperature and pressure ratings will help ensure the valve's longevity under operational conditions.

Furthermore, coating options such as Teflon or epoxy can enhance the corrosion resistance of basic valve materials, providing an additional layer of protection. It’s essential to assess the application’s conditions and overlapping regulations to determine the best material that aligns with both safety and performance standards.

**Tips:** Consulting with manufacturers about the correct material and coating is beneficial. A thorough analysis of your operational requirements can save costs in the long run by preventing premature valve failure.

| Material | Corrosion Resistance | Temperature Range (°C) | Pressure Rating (bar) | Applications |

|---|---|---|---|---|

| Stainless Steel | Excellent | -200 to 550 | 38 | Water, Oil, Gas |

| Brass | Good | -20 to 180 | 25 | Water, Air |

| PVC | Fair | 0 to 60 | 10 | Chemical Processing |

| PTFE | Excellent | -200 to 260 | 20 | Aggressive Chemicals |

| Carbon Steel | Poor | -30 to 400 | 50 | Fluids with low pH |

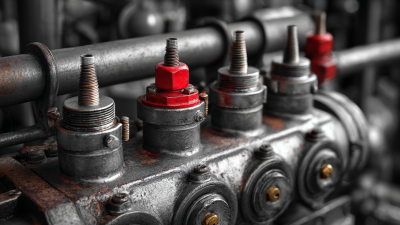

When selecting a ball valve for industrial applications, one critical decision is between manual and automated actuation systems. Manual valves require operators to physically manipulate the valve handle, making them a suitable choice for processes where infrequent adjustments are needed and where operator presence is guaranteed. These systems are often more economical and straightforward, making them ideal for smaller operations or systems where automation is unnecessary.

Conversely, automated ball valves are increasingly favored in larger, complex industrial environments. These systems utilize actuators, often powered by electricity or compressed air, allowing for remote control and integration into automated control systems. This capability not only enhances efficiency but also significantly improves safety, as operators can manage systems from a safe distance. Automated actuation is particularly advantageous in processes requiring precise control, such as in chemical processing, oil and gas, and water treatment industries, where timely intervention can prevent hazardous situations.

When selecting a ball valve for industrial applications, compliance with industry regulations and safety requirements should be at the forefront of your decision-making process. According to the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME), valves that do not meet these standards can lead to severe operational risks and regulatory penalties. For instance, the ASME B16.34 standard outlines the design, materials, and testing of valves, indicating that adherence can directly influence safety and reliability in operations.

Tips: Always verify that your chosen ball valve adheres to relevant ANSI/ASME standards and check if it has certifications like ISO 9001, which ensures robust quality management practices. Additionally, consider the valve's material compatibility and pressure ratings as outlined in API 609. This will not only enhance safety but also prolong the lifespan of your equipment, thereby reducing costly downtimes.

Ensure that your ball valve is also compliant with environmental regulations, such as the EPA's guidelines on emissions for various industries. Many manufacturing sectors are adopting stricter sustainability protocols, and using compliant valves can significantly contribute to reducing environmental impact and improving your company's compliance status. This focus on regulatory adherence will ultimately foster a safer and more efficient working environment.