In the world of industrial applications, the choice of valves can significantly influence operational efficiency and safety. Among various types of valves, plug valves stand out for their unique ability to provide reliable and precise flow control. As noted by industry expert John Smith, "Plug valves offer unmatched versatility and durability, making them an ideal solution for a wide range of industrial processes." This statement encapsulates the essence of why plug valves are favored in various sectors, from oil and gas to water treatment.

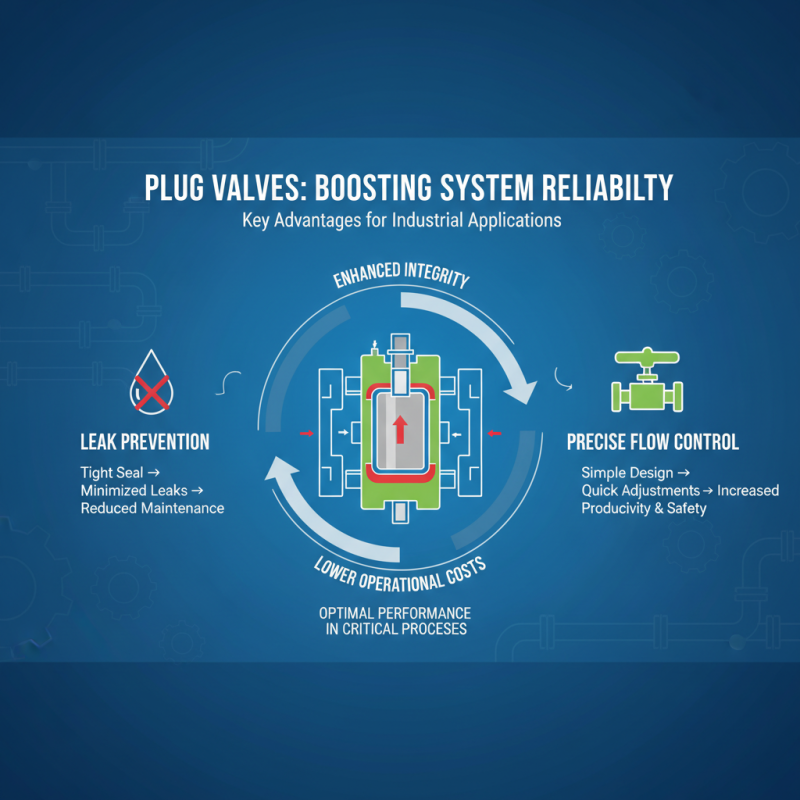

One of the primary benefits of plug valves is their simple design, which allows for quick and easy maintenance. Users appreciate the ability to achieve a tight seal and handle a range of pressure and temperature environments. Moreover, plug valves are characterized by their low flow resistance, which enhances system performance and energy efficiency. As we delve deeper into the top benefits of utilizing plug valves in industrial applications, it becomes clear that these valves not only facilitate smoother operations but also contribute to long-term savings in maintenance and energy costs.

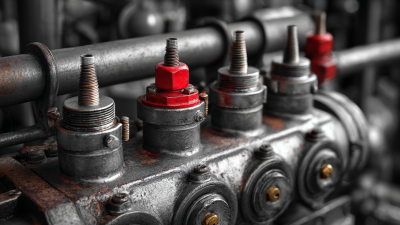

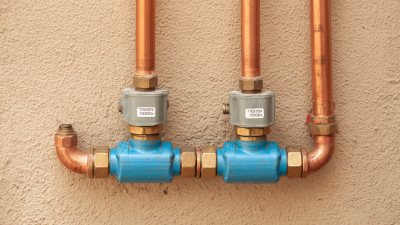

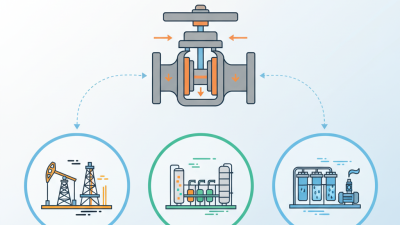

Plug valves are essential components in various industrial applications, characterized by their simple design and reliable performance. They consist of a cylindrical plug with a bore that can be rotated to control fluid flow. This straightforward mechanism allows for quick opening and closing, making plug valves ideal for on-off applications. In industries such as oil and gas, water treatment, and chemical manufacturing, their ability to handle high-pressure and high-temperature conditions is highly valued.

One of the key advantages of plug valves is their versatility in different media, including liquids, gases, and slurries. Their design minimizes turbulence and pressure drop, which enhances system efficiency. Additionally, plug valves generally require less maintenance due to their simple structure and fewer moving parts, contributing to lower operational costs. As industries continue to prioritize efficiency and reliability, the use of plug valves in applications ranging from flow regulation to isolation continues to grow, cementing their role as a staple in modern industrial infrastructure.

Plug valves are increasingly favored in various industrial applications due to their distinct flow control advantages. One of the key benefits is the ability to provide a tight seal, significantly reducing leakage during operation, which is critical in industries handling hazardous or valuable fluids. According to a 2022 report from the International Society of Automation, plug valves can achieve leak rates as low as 0.1% of the flow, outperforming many other valve types. This feature not only enhances safety but also improves the efficiency of fluid management systems.

Another major advantage of plug valves is their straightforward operational design, which allows for rapid opening and closing with just a quarter turn. This characteristic is particularly beneficial in environments requiring quick response times, such as in oil and gas facilities. The ease of maintenance associated with plug valves also contributes to their growing popularity; studies indicate a 30% reduction in service time compared to other valve types, resulting in substantial cost savings over time.

Tips: When selecting plug valves for specific applications, consider the material compatibility with the media being transported. Additionally, it's essential to evaluate the valve's pressure and temperature ratings to ensure optimal performance. Regular maintenance checks can further enhance the longevity and reliability of these valves, minimizing unplanned downtime in industrial operations.

Plug valves are increasingly recognized for their remarkable durability and longevity, particularly in harsh industrial environments. These valves are engineered to perform reliably under extreme conditions, making them ideal for applications where pressure, temperature, and corrosiveness pose significant challenges. According to industry reports, plug valves can maintain their functional integrity over extended periods, often exceeding 20 years of service life, even in demanding settings such as chemical processing and oil and gas industries. This extended lifespan not only reduces the frequency of replacements but also minimizes maintenance costs, leading to increased operational efficiency.

The inherent design of plug valves contributes significantly to their durability. Typically constructed from robust materials such as stainless steel or ductile iron, they can withstand severe environments characterized by high pressure and temperature fluctuations. Studies have shown that plug valves can operate effectively in a temperature range from -20°F to 400°F, which positions them favorably against other valve types that may falter under similar conditions. Furthermore, their simple structure allows for easy cleaning and maintenance, further enhancing their longevity. As industries continue to seek ways to improve reliability and reduce downtime, the selection of plug valves in system designs stands out as a strategic choice for ensuring sustained performance and cost-effectiveness.

Plug valves are renowned for their efficiency in industrial applications, particularly when it comes to reducing maintenance costs. One of the primary benefits of using plug valves is their simple design, which minimizes the number of moving parts. This simplicity results in decreased wear and tear over time, allowing for longer intervals between maintenance checks and replacements. Unlike other types of valves that may require intricate adjustments or frequent repairs, plug valves operate smoothly, which translates to lower labor and material costs for upkeep.

Moreover, plug valves offer excellent sealing capabilities, which enhance their durability and reliability. This effective sealing minimizes the risk of leaks, reducing the need for costly emergency repairs and downtime. In many cases, the robust design of plug valves also allows them to handle various fluids, including slurries and viscous liquids, without compromising performance. As a result, industries can achieve significant savings by choosing plug valves, thanks to their reduced maintenance requirements and lifespan longevity, ultimately leading to enhanced operational efficiency and cost-effectiveness.

| Benefit | Description | Impact on Maintenance Costs |

|---|---|---|

| Reduced Leakage | Design minimizes leakage, enhancing safety and environmental compliance. | Decreases costs associated with product loss and environmental penalties. |

| Simple Design | Fewer moving parts lead to straightforward maintenance and reliability. | Reduces labor time and costs for maintenance tasks. |

| Low Torque Requirements | Easier actuation of valves, leading to less wear over time. | Lowers actuator maintenance frequency and costs. |

| Efficient Flow Control | Provides quick and precise control of flow rates. | Minimizes product waste and improves overall efficiency of operations. |

| Corrosion Resistance | Materials designed to withstand harsh environments. | Lowers replacement and repair costs over time. |

| Versatile Applications | Suitable for various industries including oil, gas, and water treatment. | Reduces the need for multiple valve types, lowering inventory costs. |

| Safety Enhancement | Minimizes risk of leaks and failures in critical applications. | Reduces potential costs associated with accidents or spill clean-ups. |

| Space Saving Design | Compact size suitable for tight installation spaces. | Decreases installation costs and optimizes facility layouts. |

| Quick Installation and Maintenance | Designed for easy assembly and disassembly. | Reduces downtime during maintenance, saving labor costs. |

Plug valves are known for their significant contribution to system performance and reliability in various industrial applications. One of their primary advantages is the ability to provide a tight seal, minimizing leaks that can compromise operational efficiency. This leakage prevention enhances the overall integrity of the system, leading to reduced maintenance needs and lower operational costs. In processes where precise flow control is critical, plug valves excel due to their straightforward design, allowing for quick and easy adjustments. This responsiveness contributes to maintaining optimal conditions within the system, thereby enhancing productivity and safety.

Additionally, plug valves are designed to withstand harsh operating conditions, making them a reliable choice for industries dealing with corrosive fluids or high-temperature environments. Their robust construction ensures durability, which translates into a longer lifespan and fewer replacements needed over time. This longevity not only improves system reliability but also reduces downtime, as fewer valve replacements and maintenance activities are required. The combination of a tight seal and durability underscores the importance of plug valves in optimizing system performance, ultimately leading to a more efficient and reliable industrial operation.