In recent years, the industrial sector has seen a significant evolution in fluid control technologies, with ball check valves emerging as essential components in various applications. According to a report by Market Research Future, the global ball check valve market is expected to grow at a CAGR of 5.3% from 2020 to 2027, driven by advancements in manufacturing processes and an increasing demand for efficient fluid handling systems. Ball check valves play a crucial role in preventing backflow and ensuring a consistent flow of fluids within pipelines, making them instrumental in industries such as water treatment, oil and gas, and chemical processing.

The efficacy of ball check valves is attributed to their simple design and reliability. These valves utilize a spherical ball that serves as a closure element, automatically sealing the flow path when backflow occurs. This mechanism not only protects infrastructure and maintains system integrity but also enhances operational safety and efficiency. With the rising emphasis on sustainable practices and resource conservation, industries are progressively adopting ball check valves to optimize their processes and reduce wastage. Identifying the top benefits and applications of ball check valves can further illuminate their integral role in contemporary industrial systems, highlighting why they are becoming a preferred choice among engineers and facility managers alike.

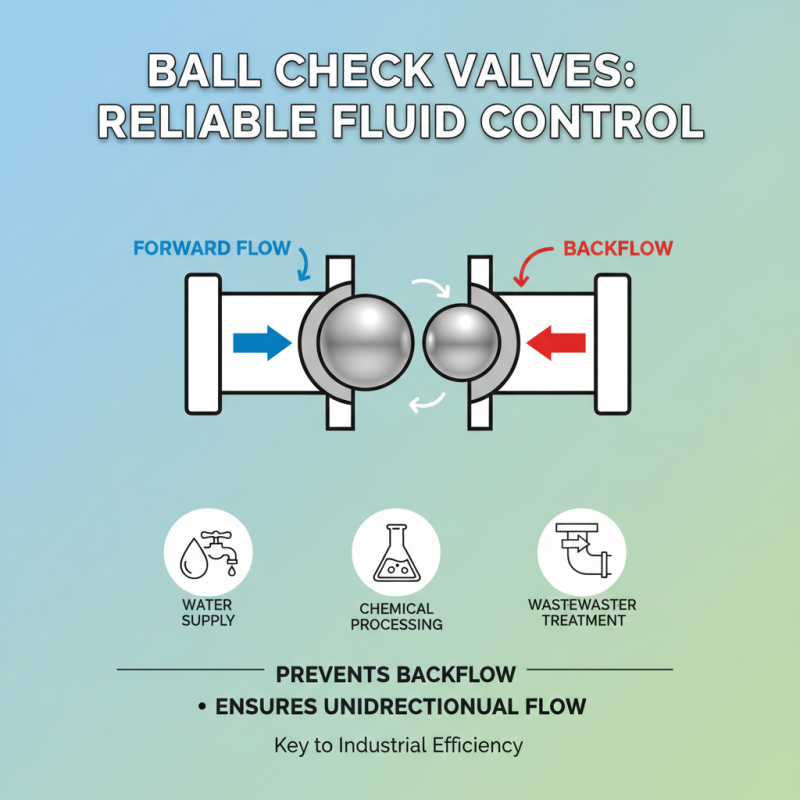

Ball check valves play a crucial role in various industrial applications, leveraging their unique design to ensure efficient fluid flow while preventing backflow. These valves utilize a spherical disc that moves within a cylindrical body, allowing fluid to pass through in one direction while sealing off reverse flow. This mechanism is especially useful in systems where maintaining directionality is critical, such as in water supply systems, chemical processing, and wastewater treatment.

In industrial contexts, ball check valves are favored for their reliability and minimal maintenance requirements. Their simple design reduces wear and tear, providing long service life even in challenging environments. Beyond fluid control, these valves contribute to system safety by preventing contamination and protecting pumps and compressors from potential damage caused by backflow. Their versatility also enables them to be integrated into various piping systems, accommodating different sizes and pressure ratings, making them essential components across multiple sectors.

Ball check valves play a crucial role in various industrial systems, offering numerous benefits across different applications. One of the key advantages is their ability to prevent backflow in pipelines, ensuring the smooth and efficient operation of fluid transport systems. According to a report by the Global Market Insights, the ball valve market is projected to surpass USD 17 billion by 2025, indicating a growing reliance on these devices for maintaining system integrity and reliability. By utilizing a simple yet effective spherical disc mechanism, ball check valves are capable of providing a tight seal, significantly reducing the risk of leakage, which is essential for industries such as oil and gas, water treatment, and chemical processing.

In addition to backflow prevention, ball check valves offer ease of maintenance and a long operational lifespan, making them a cost-effective choice for manufacturers. Their robust construction and ability to handle a wide range of temperatures and pressures enhance their applicability in diverse environments. The Fluid Power Journal emphasizes that the efficiency of manufacturing processes can increase by up to 25% when utilizing reliable check valves, including ball check valves, as they minimize downtime caused by maintenance and replacement. By integrating ball check valves into systems, industries can not only optimize performance but also improve safety standards, as these valves help contain potentially hazardous substances.

This bar chart illustrates the percentage of use of ball check valves across various industries, highlighting their importance in maintaining fluid control and preventing backflow.

Ball check valves are essential components in various fluid control systems, providing reliable and efficient solutions across multiple industrial applications. These valves work on a simple yet effective principle, allowing fluid to flow in one direction while preventing backflow. This functionality is particularly crucial in systems where maintaining flow direction is vital for safety and operational efficiency.

Commonly, ball check valves are used in waste management systems, where they help manage the flow of wastewater and prevent contamination of clean water supplies. Their robust design ensures they can withstand harsh conditions commonly found in waste treatment facilities. Additionally, in pumping applications, these valves protect pump systems from damage caused by reverse flow, thus extending the lifespan of equipment and reducing maintenance costs.

Another significant application is in irrigation systems, where ball check valves play a critical role in preventing water from flowing backwards after being pumped into fields. By ensuring a constant flow, these valves help maintain pressure, enhancing the efficiency of water distribution. Furthermore, in chemical processing industries, ball check valves facilitate the safe handling of various fluids by preventing leaks and ensuring a controlled environment, which is vital for operational safety and compliance with industry regulations.

| Application | Benefit | Industry | Operating Pressure (psi) | Temperature Range (°F) |

|---|---|---|---|---|

| Wastewater Treatment | Prevents backflow, ensuring proper wastewater flow | Environmental | 150 | 32 to 140 |

| Pumping Systems | Enhances efficiency by preventing reverse flow | Manufacturing | 200 | 50 to 180 |

| Chemical Processing | Resistant to corrosive fluids and high pressure | Chemical | 300 | -20 to 250 |

| HVAC Systems | Maintains optimal flow dynamics for heating and cooling | HVAC | 100 | 40 to 120 |

| Oil and Gas | Prevents backflow in pipelines, enhancing safety | Oil and Gas | 400 | -40 to 300 |

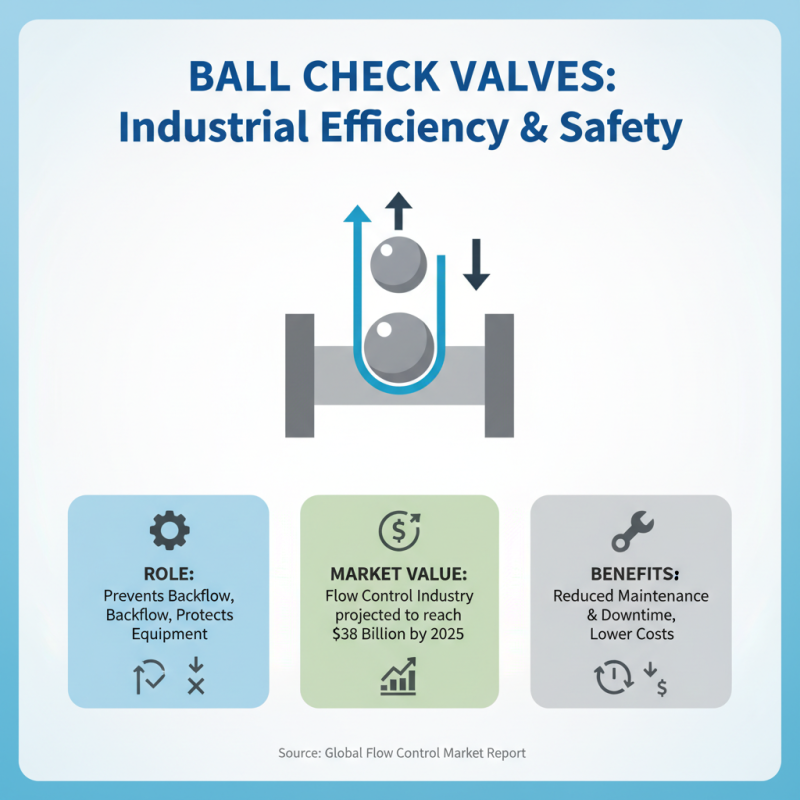

Ball check valves play a crucial role in enhancing the efficiency and safety of industrial systems. These valves are designed to allow fluid to flow in one direction while preventing backflow, effectively safeguarding vital processes and equipment. According to a report by the Global Flow Control Market, the value of the flow control equipment industry is projected to reach $38 billion by 2025, emphasizing the growing reliance on effective fluid management technologies such as ball check valves. Their simplicity in design allows for reduced maintenance requirements, which translates to lower operational costs and minimized downtime in industrial settings.

Additionally, ball check valves contribute significantly to system safety by preventing backflow that could lead to potentially dangerous situations, such as contamination or pressure build-up. The Hydraulic Institute notes that improper flow management can result in equipment failure, leading to severe safety hazards and costly repairs, estimated to account for nearly 20% of maintenance costs in certain industrial applications. By ensuring a reliable, one-way flow and effectively managing pressure, ball check valves not only enhance system efficiency but also provide a safeguard against the inherent risks associated with fluid transport, ultimately making them an indispensable component in modern industrial applications.

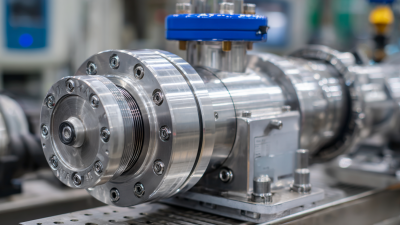

Proper maintenance of ball check valves is essential for ensuring optimal performance in industrial systems. Regular inspection is crucial; operators should check valves for any signs of wear, corrosion, or blockage that could impede functionality. Cleaning the valve seats and ensuring that ball movement is unobstructed can significantly enhance the reliability and longevity of the valves. It is advisable to adhere to a scheduled maintenance plan, which may include periodic disassembly for thorough examination and lubrication of moving parts.

In addition to routine inspections, implementing best practices during operation can help reduce the likelihood of premature failure. This includes monitoring the pressure and flow rates to ensure they remain within the valve's specifications. Installing the valves in the correct orientation and ensuring proper alignment during installation can mitigate problems related to vibration and misalignment. Educating operators about the potential impacts of fluid characteristics, such as viscosity and temperature, on valve performance is also important. By prioritizing maintenance and best practices, industrial systems can achieve greater efficiency and reliability with ball check valves.